As the core equipment of photovoltaic storage integration and microgrid, photovoltaic inverters have developed from a single power conversion device to a comprehensive energy hub integrating energy management, intelligent control, and system protection. Its technological innovation and market penetration depth directly determine the scale development process of the new energy industry. Therefore, the testing of photovoltaic inverters is crucial. In this article, Ainuo will introduce you how to test photovoltaic inverters based on its own product series.

What Is a Photovoltaic Inverter?

Photovoltaic energy storage inverter is a power electronic device that combines photovoltaic power generation system and energy storage system, mainly responsible for the bidirectional conversion and power management functions between DC and AC.

I. Definition and core role

Power conversion: Convert the DC power generated by photovoltaic panels into AC power for load or grid use, and convert the excess power of the grid or photovoltaic system into DC power and store it in the battery.

Energy storage management: The storage and release of electric energy is realized through energy storage devices (such as batteries) to optimize energy utilization efficiency.

System coordination: As a "bridge" between photovoltaic power generation and energy storage equipment, it supports grid-connected operation, off-grid power supply and hybrid mode switching.

II. Working Principle

1. DC Conversion

The photovoltaic panel outputs DC power to the inverter, and after the voltage is adjusted by the boost circuit, it is converted into AC power by the inverter bridge circuit.

2. Energy Storage Charging and Discharging

Charging phase: Convert the AC power of the photovoltaic or power grid into DC power and store it in the battery.

Discharging phase: Invert the DC power of the battery into AC power to supply power when there is insufficient sunlight or the power grid is out of power.

Intelligent Control: Automatically switch the charging and discharging mode according to the power grid status, load demand and energy storage capacity to ensure stable power output.

3. Core Functions

Energy Management: Balance power generation and power demand, and improve the self-use rate of photovoltaic power generation.

On/off-grid switching: When the power grid is normal, it is connected to the grid, and when it is abnormal, it switches to off-grid mode for independent power supply.

Power Quality Control: Ensure that the output voltage and frequency are synchronized with the power grid to avoid harmonic interference.

4. Application Scenarios

Home/Industrial and Commercial Energy Storage: Used for peak and valley electricity price arbitrage, emergency backup power supply and other scenarios.

Microgrid support: Build off-grid power systems in remote areas or islands.

Grid frequency and peak regulation: Assist the grid to balance load fluctuations and improve the ability to absorb renewable energy.

How To Test Photovoltaic Inverters?

The performance test of photovoltaic inverters needs to be tested in multiple dimensions to ensure their safe, stable and efficient operation.

I. Core Test Items

1. Efficiency Test

Conversion efficiency: Measure the DC-to-AC efficiency of the inverter under different loads (such as 25%, 50%, 100%), and the maximum efficiency is required to be no less than 94%.

Dynamic efficiency: Simulate sudden changes in light (such as a sudden drop in irradiance from 1000W/m² to 500W/m²) to test the response speed and accuracy of the MPPT algorithm.

Low load efficiency: Evaluate the operating efficiency of the inverter at low power output to avoid excessive standby energy consumption.

2. MPPT (Maximum Power Point Tracking) Test

Use a programmable DC power supply to simulate the changes in the I-V curve of the photovoltaic array to verify whether the inverter can quickly lock the maximum power point when the irradiance changes suddenly or the temperature fluctuates. The dynamic efficiency must reach more than 99%.

3. Protection Function Test

Grid abnormal protection: simulate overvoltage, undervoltage, overfrequency, underfrequency and other faults, detect whether the inverter is disconnected and alarmed within the set time.

Island effect protection: simulate the grid power outage scenario through the RLC resonant circuit to verify whether the inverter can cut off the grid connection within 0.2 seconds.

DC side protection: detect the response capability of DC reverse connection, overvoltage and insulation fault.

4. Grid Adaptability Test

Harmonics and THD (total harmonic distortion): measure the harmonic content of the output current, which must comply with the IEC 61000-3-2 standard.

High and Low Voltage Ride Through (LVRT/HVRT): simulates instantaneous voltage drop or surge of the power grid to test the inverter's ability to maintain grid connection.

5. Electromagnetic Compatibility (EMC) Test

Radiated interference and conducted interference tests are performed to ensure compliance with EN 55032 and other standards.

6. Environmental Adaptability Test

Execute operation tests in high temperature (+50℃), low temperature (-25℃), and hot and humid environments to verify the stability of the inverter.

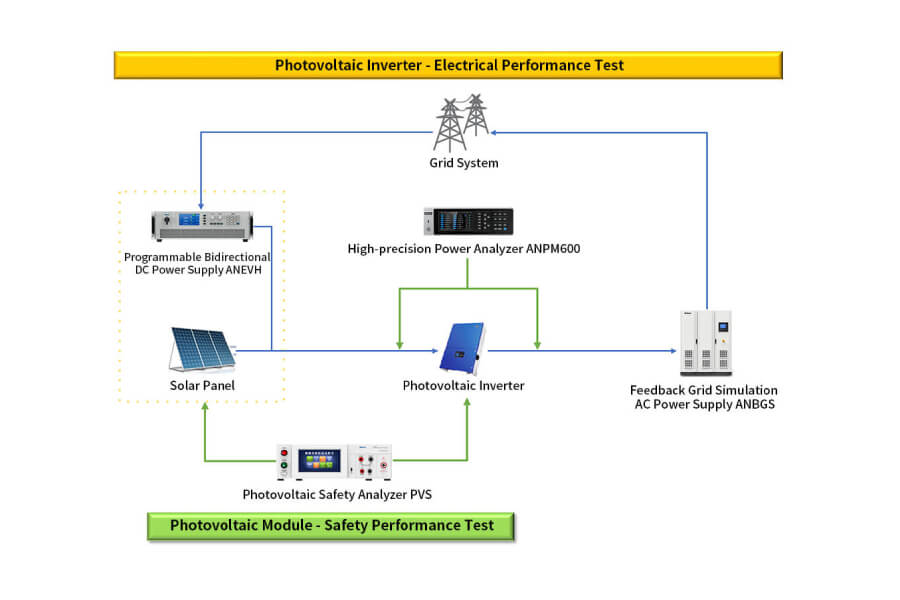

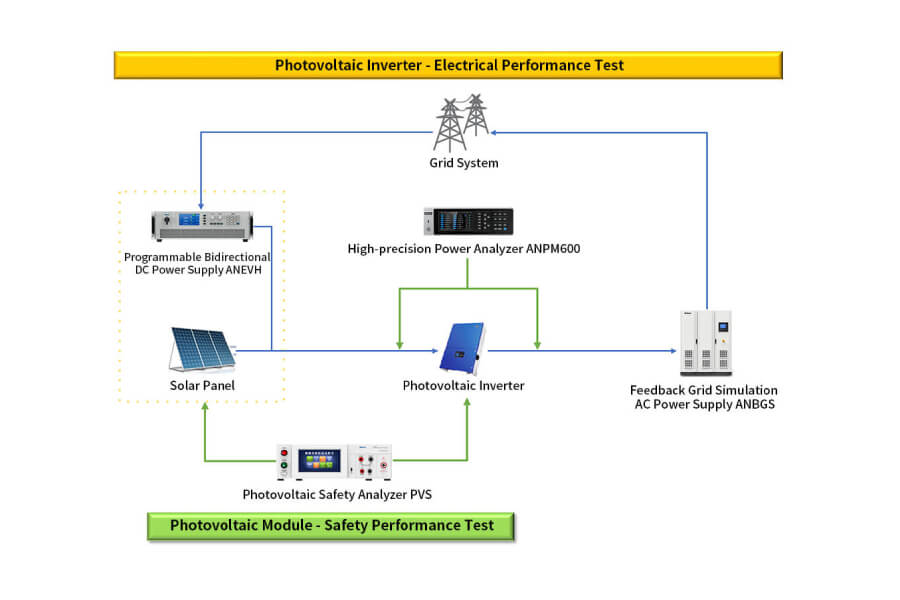

II. Test System Composition

1. Hardware Equipment

DC Power Simulator: such as Ainuo ANEVH series, accurately simulates the I-V characteristic curve of the photovoltaic array.

AC Load/Grid Simulator: such as Ainuo AN236 series, reproduces grid fluctuations and fault scenarios.

Power Analyzer: measures input/output power, harmonics and other parameters with an accuracy of 0.1%. Ainuo ANPM600 series power analyzer is recommended.

Data Acquisition System: records operating data such as temperature and voltage in real time.

2. Software Control

The automated test platform controls the test process, dynamically generates irradiance curves and grid fault sequences, and generates standardized reports.

III. Examples of Key Test Processes (Taking Islanding Effect as an Example)

1. Build a test platform: including separation switches (K1, K2) and adjustable RLC resonant loads, and the load power must match the rated power of the inverter.

2. Adjust parameters: Set Qf=1.0±0.05, and calibrate the resonant frequency of the RLC circuit to be consistent with the rated frequency of the inverter.

3. Trigger islanding: Disconnect the grid connection (K1) and observe whether the inverter stops supplying power within 0.2 seconds.

IV. Performance Evaluation Standards

Functional verification: The output voltage, frequency, and waveform must meet the grid connection requirements.

Efficiency and stability: There is no abnormal fluctuation in long-term operation, and the temperature rise of components does not exceed 10°C.

Safety compliance: Pass electrical safety tests (such as insulation resistance, grounding connection) and EMC certification.

Finally

Through the above systematic tests, the energy efficiency, reliability and grid compatibility of photovoltaic inverters can be comprehensively evaluated, providing technical support for practical applications.