New Energy Vehicle Industry Background

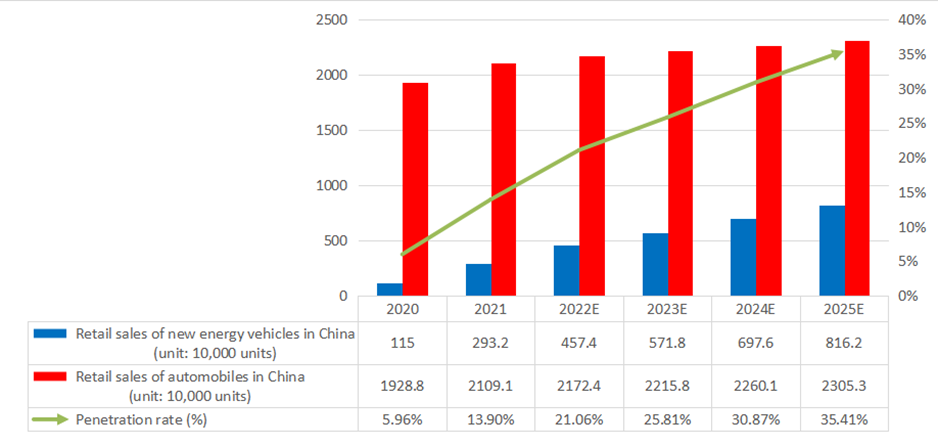

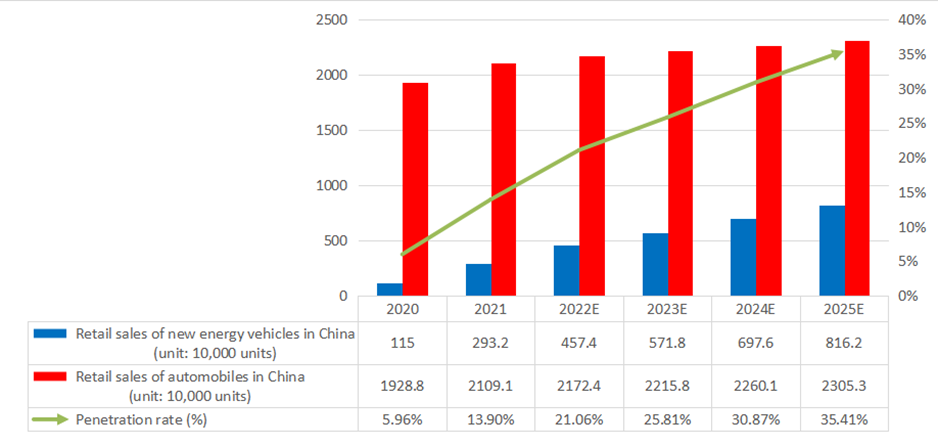

In recent years, the new energy industry has developed rapidly under the strong support of the government, driving the rapid rise of new energy vehicles in the fields of household and commercial use. As an important measure of the dual carbon goal, the new energy vehicle industry has ushered in unprecedented opportunities, and has gradually entered a period of rapid development in the true sense. Moreover, there was an "explosive" increase in 2021. With the improvement of the overall awareness of society, the market environment has shifted from "policy-driven" to a new stage of "market-driven" development, and the production and sales of new energy vehicles have experienced explosive growth.

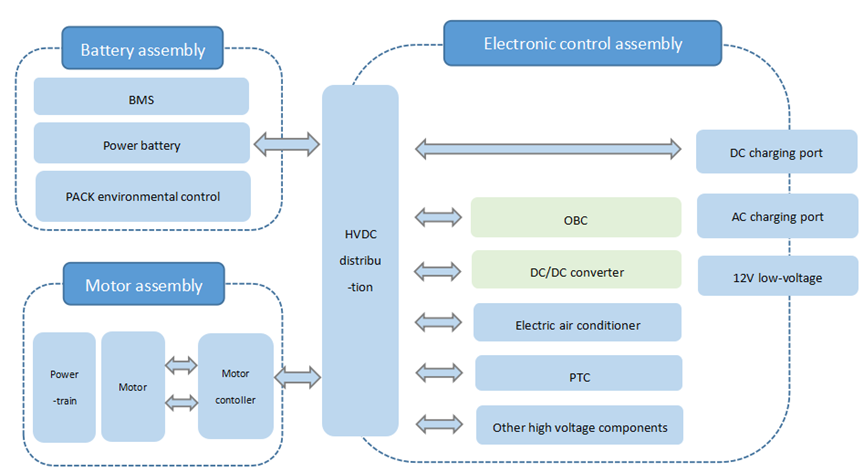

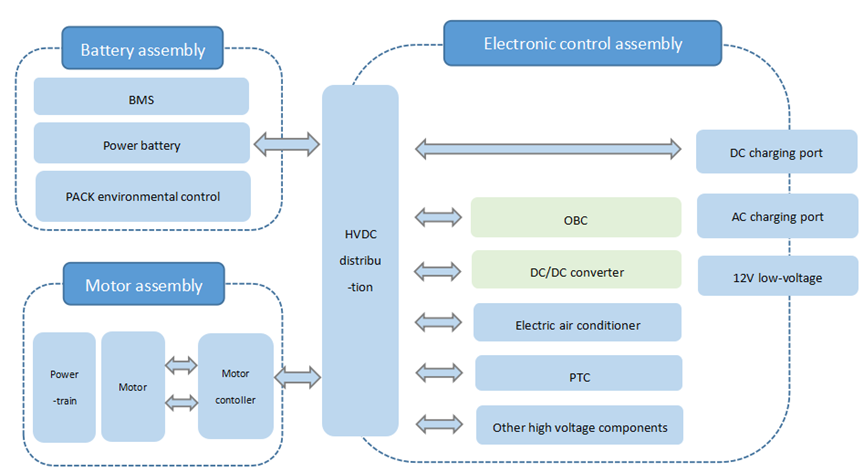

The outstanding difference between new energy vehicles and traditional vehicles is the big three electric components and the small three electric components. The big three electric components refer to the motor, battery and electronic control; the small three electric components refer to the DC/DC converter and OBC. The big & small electric components generally constitute the battery, motor and high-voltage electronic control three major assembly systems. Among them, the D2D converter and OBC are the core components of new energy vehicles, and directly determine the safety and energy saving of new energy vehicles.

(Picture source: Internet)

OBC/D2D Industry Background

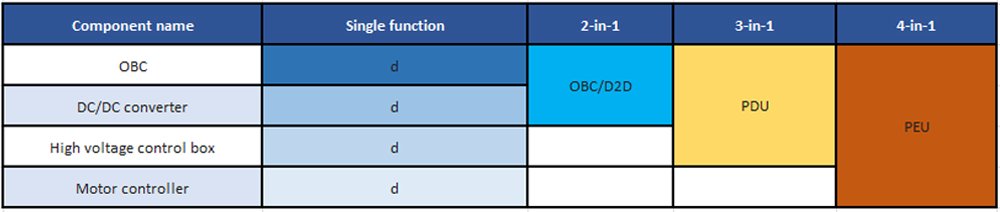

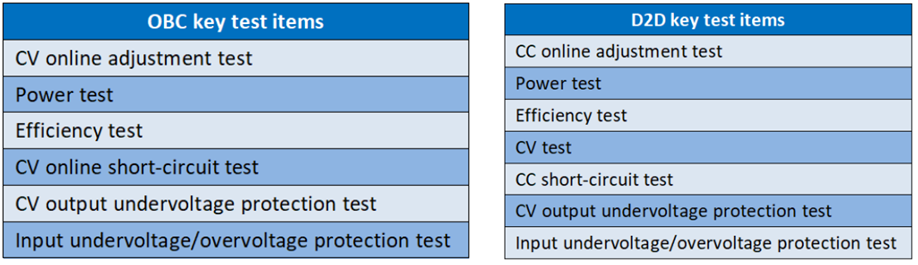

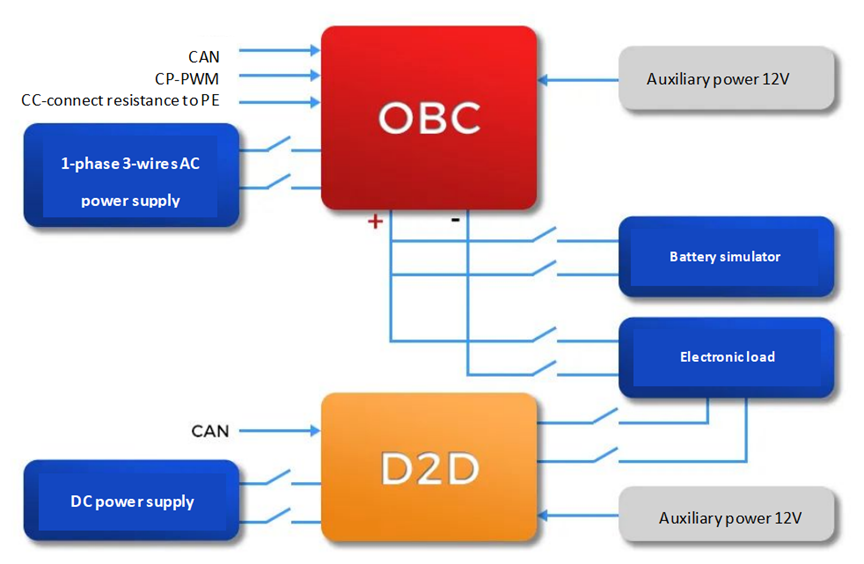

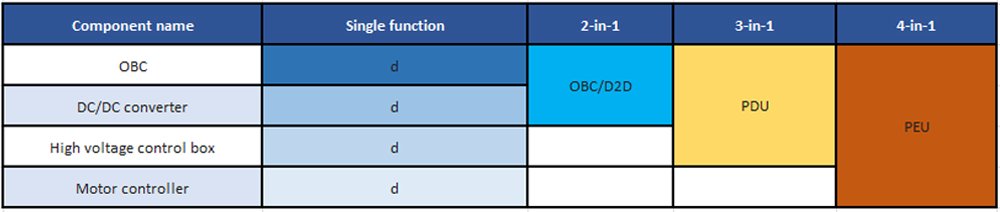

OBC/D2D is the core component and the power source of electric vehicles. It converts the alternating current on the grid into direct current that can meet the charging requirements of electric vehicle batteries. And it protects and controls the charging process of the battery according to the characteristics of the battery to avoid damage to the battery due to improper charging. Important parts of the car. In China, the domestic OBC companies have realized the industrialized production of OBC through R&D with OEMs. And they are actively expanding their production scale, enhancing their technological advantages and seizing market share. In order to reduce costs, reduce space occupation, and enhance the core competitiveness of technology, electronic control components such as OBC/D2D are increasingly integrated. The integration method is as follows:

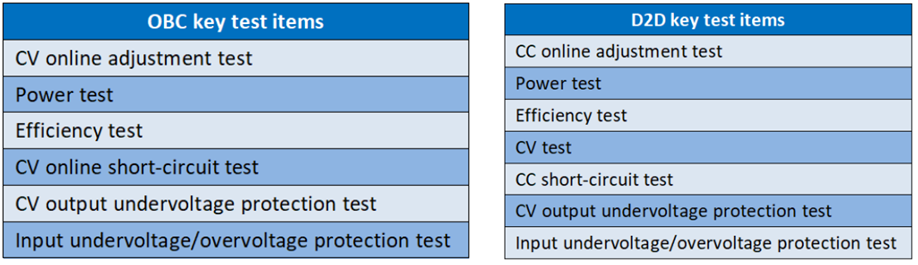

OBC/D2D Core Testing Requirements

The current power range of OBC is mainly 3.3KW, 6.6KW, 10KW, 23KW, and there will be more power in the future.

OBC/D2D Test Solutions

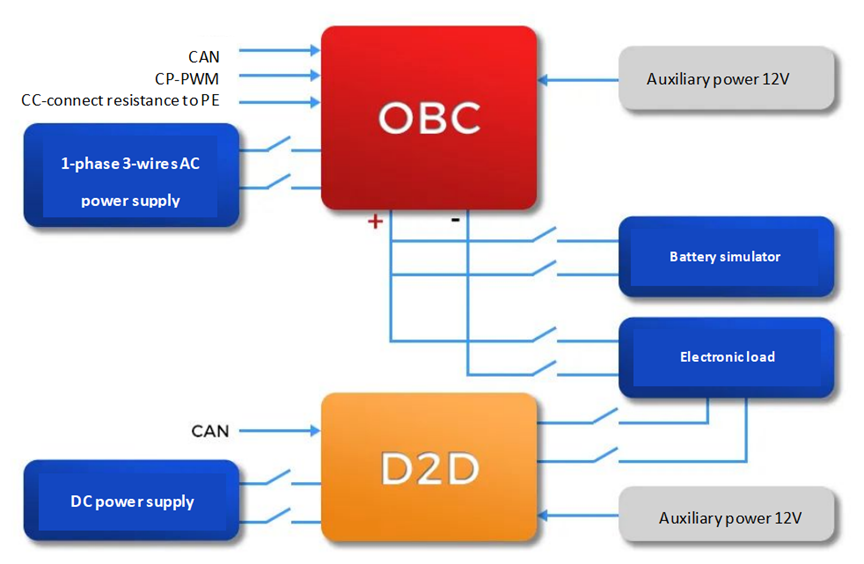

To realize the above tests, it is necessary to configure the power source including DC power source, AC power source, as well as power analyzer, DC electronic load and other instruments. These instruments can be selected from Ainuo’s instruments.

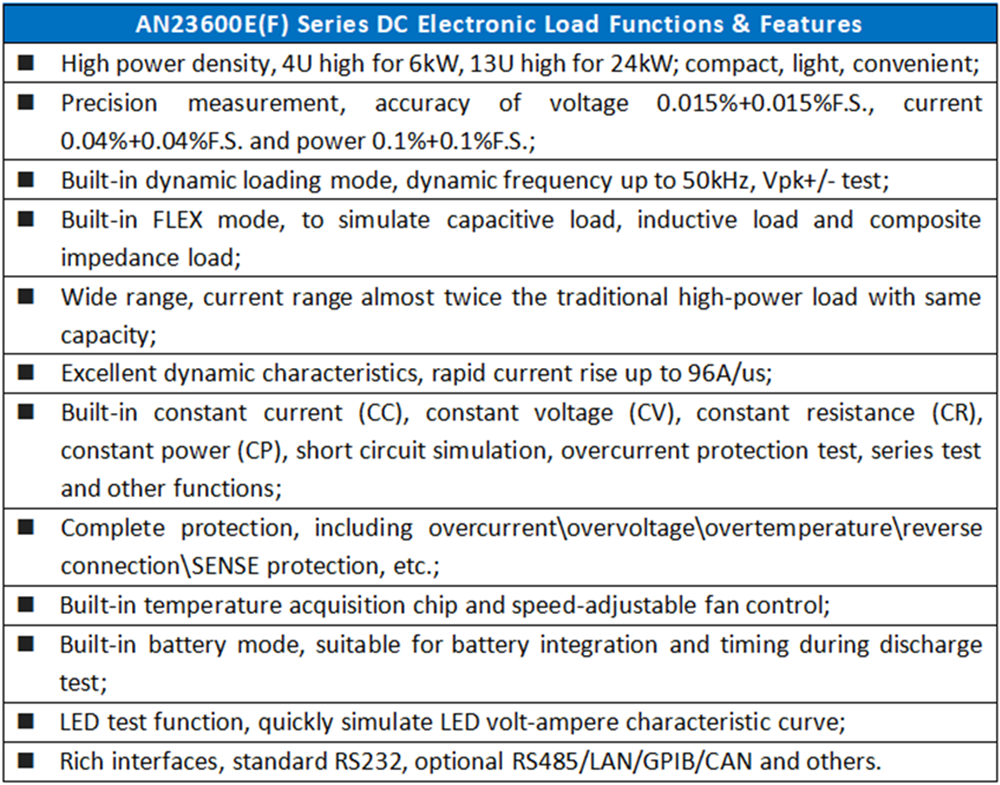

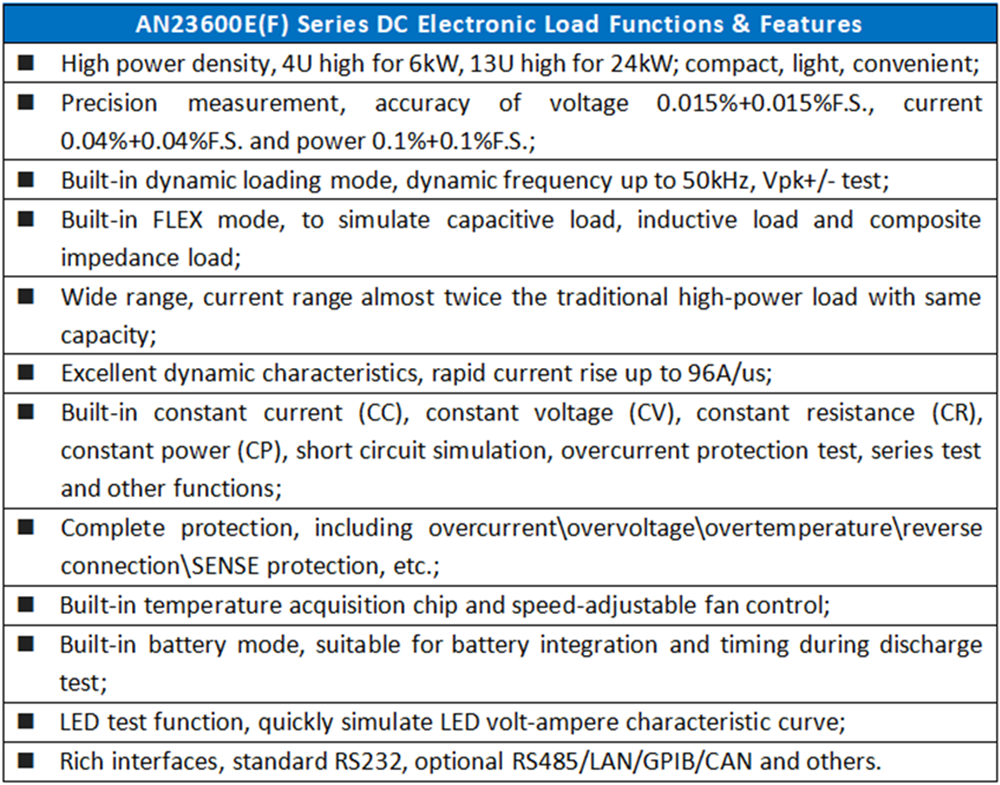

Relevant test items put forward high requirements for the dynamic, rapidity and adaptability of electronic loads. Here we choose Ainuo AN23600E series electronic load, whose features are as follows:

The AN23600E series DC electronic load has rich functions, high power density, high precision and strong load adaptability. It has the following characteristics:

According to QCT 895-2011 Conductive On-board Chargers for Electric Vehicles, GB/T 24347-2009 Electric Vehicles DC/DC Converters and other standards, combined with the OBC/D2D key test items mentioned above, higher requirements are put forward for electronic loads, here is only a partial analysis:

CV Under-voltage Protection Test

The under-voltage protection is mainly to find the under-voltage protection point. Due to the large voltage fluctuation during the under-voltage testing process, the under-voltage protection point is often unstable, resulting in a high product failure rate. The AN23600E series electronic load has a built-in digital controller. Adopting an adaptive algorithm, during the undervoltage testing process, the overshoot amplitude is minimized to the greatest extent, and the undervoltage protection point is accurately located;

Short-circuit Protection Test

The short-circuit protection test is a limit test that simulates an overload test. It requires the electronic load to reach the maximum current value in a short time (usually within 5ms). This requires the electronic load to rise as fast as possible. The The fastest slope of AN23600E series electronic load can reach 96A/us, which can fully meet the short-circuit test requirements.

OBC/D2D Compatibility Test

OBC has the characteristic of high voltage and small current, and it is mainly used in CV mode. D2D has the features of low voltage and high current, and it is mainly used in CC mode. To be compatible with two product characteristics at the same time, AN23600E series electronic load PID control algorithm is fast to 2us cycle. The cascade loop control technology realizes the characteristics of stability, accuracy and speed in the automatic control principle, which greatly broadens the adaptability of the measured source.