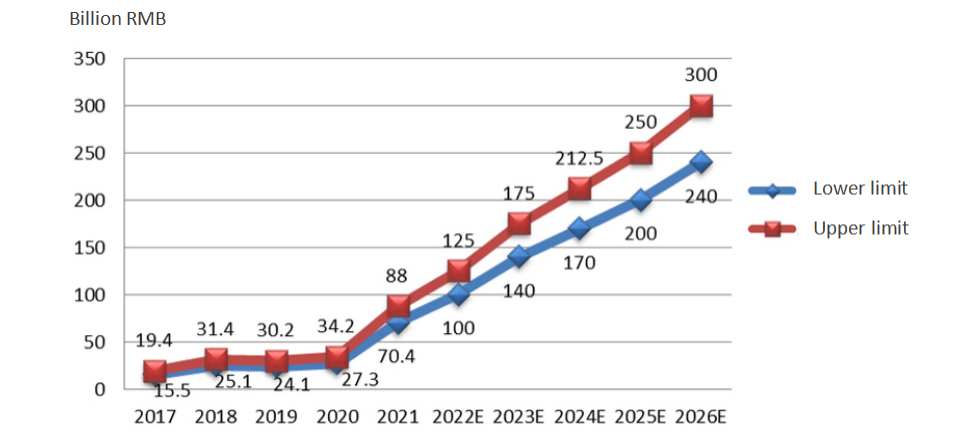

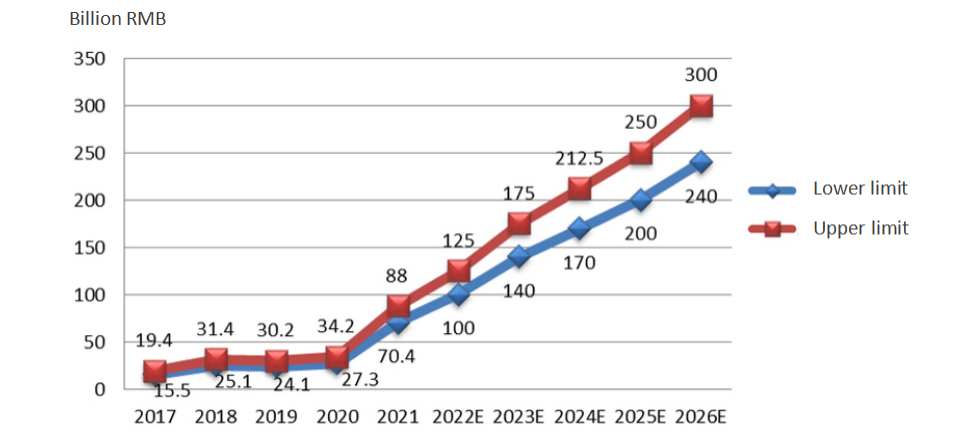

OBC Market Expectation

In recent years, with the vigorous development of new energy vehicle industry, demand for on-board charger, as the key component of electric car, has soared. According to the forecast data of Zhiyan Consulting Center and Toubao Research Institute of China, by 2025, the domestic OBC market size of on-board chargers will reach 25 billion RMB, with an average annual compound growth rate of 28%.

Chart #1 OBC Market Forecast

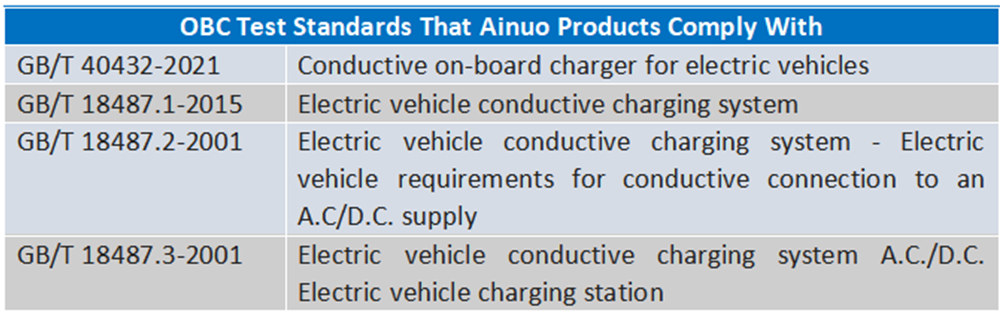

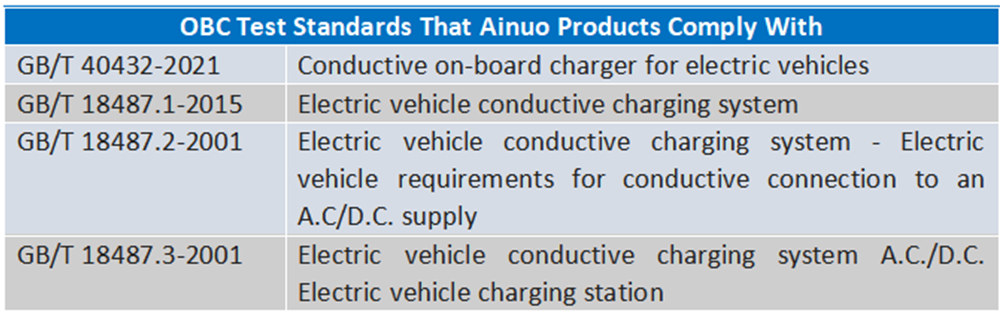

Mandatory Test Requirements for OBC

In order to promote technical upgrade of OBC, strengthen safety regulations and improve product quality, China has issued a series of standards and specifications. Therefore, OBC manufacturers need to conduct comprehensive tests on functions and performance of OBC according to the standards in the production of OBC and whole vehicle.

Chart #2 OBC Test Standards That Ainuo Products Comply With

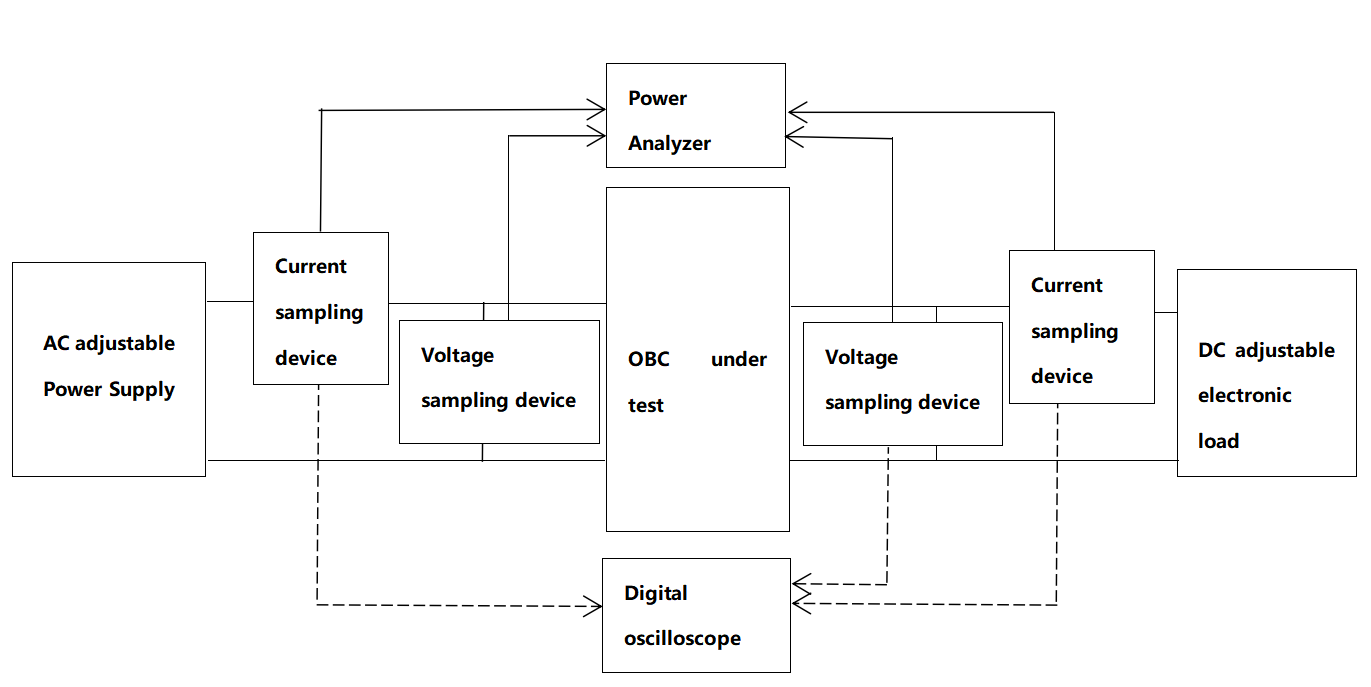

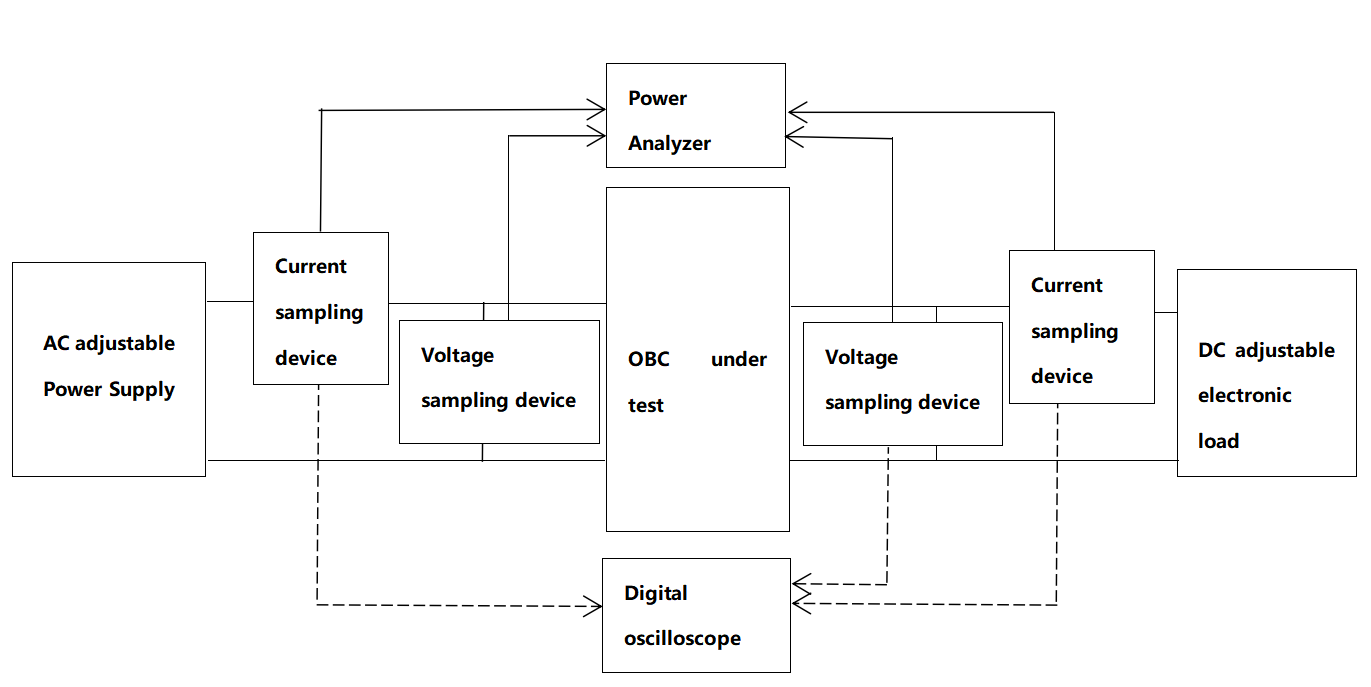

OBC electrical performance tests include: input voltage range test, input frequency range test, startup input impulse current test, harmonic current test, power factor and power supply environment simulation test (reference standard: GB/T 40432-2021).

Chart #3 OBC Test Schematic Diagram

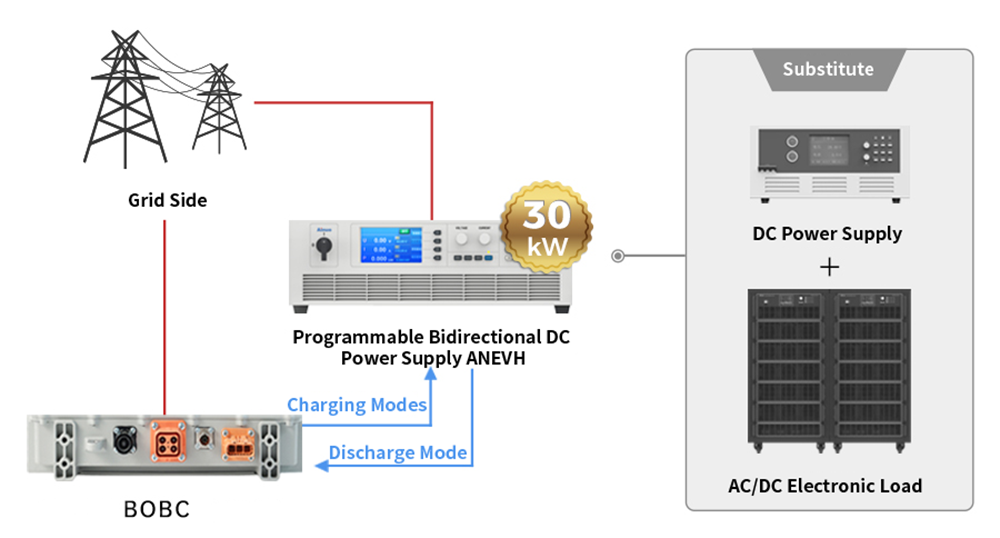

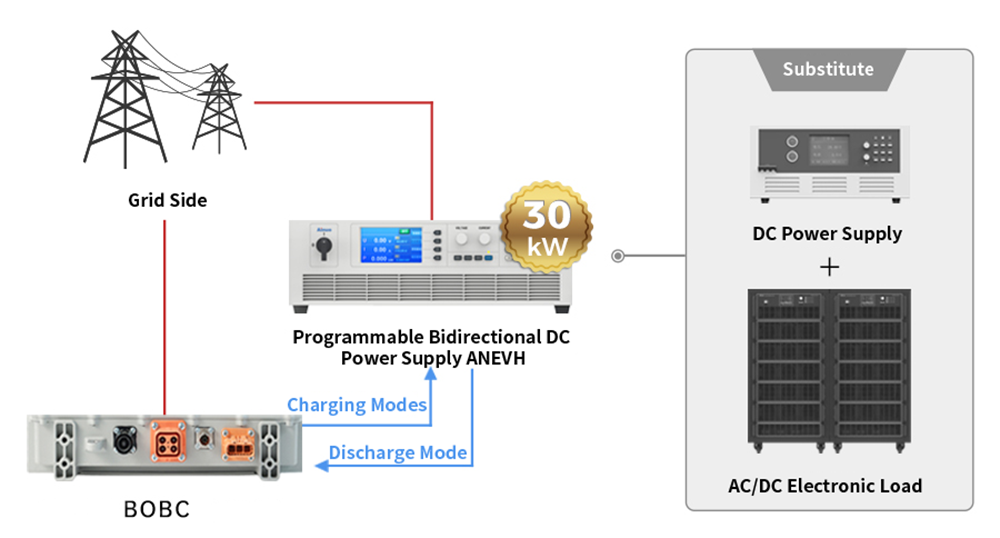

Bidirectional On-board Charger (BOBC)

With the development of electric vehicle technology, bidirectional inverter technology has gradually become the standard configuration of OBC. In addition to charging for power batteries, bidirectional on-board charger can realize V2G (Vehicle to Grid) feedback power to the grid, and V2V, V2L, V2H/B vehicle-charge-vehicle and power discharge. It even achieves the interaction of building power and forms a micro-grid power supply system, which increases the convenience and flexibility of power supply. The proportion of BOBC is increasing, while its test steps are more complicated and inefficient than traditional OBC tests.

Improves BOBC Testing Efficiency

Ainuo ANEVH bidirectional DC power supply improves bobc testing efficiency.

Deeply cultivated in the electrical testing industry for 30 years, Ainuo Instrument understands the pain points in the testing of new energy vehicles. The specially developed ANEVH bidirectional programmable DC power supply can simulate power batteries and grid to support BOBC related tests efficiently. It is a good assistant for manufacturers who need simplify and upgrade test circuits. ANEVH can save additional equipment costs, greatly improve the testing efficiency in the R&D and production of BOBC, and support production capacity growth.

ANEVH bidirectional DC power supply integrates source and load functions into one device. It has bidirectional energy flow, ultra-fast dynamic response and 1.5ms forward and reverse fast switching speed. Moreover, it adopts automatic energy feedback function and has the advantages of energy saving and consumption reduction. It is also equipped with active power factor correction technology, and the full load power factor exceeds 0.99.

ANEVH bidirectional DC power supply has a compact size of only 3U. The voltage range of a single machine is 0-2250V, the current range is 0-510A, the maximum output power is 30KW. What’s more, ANEVH products support parallel connection of multiple devices, and the maximum power can reach 1MW, meeting the needs for higher power testing.

Built-in DIN40839, ISO-16750-2 and ISO21848 standard automotive power grid voltage curves, ANEVH can freely generate a variety of waveforms. Its excellent characteristics and rich test functions are suitable for a variety of test occasions.

Chart #4 BOBC Test Schematic