Market of New Energy Vehicle Drive Motor

China’s new energy vehicle sales in 2021 reached 2.93 million units with a year-on-year increase of 154.96%. And the market penetration rate has reached 13.4%. With the rapid development of the new energy vehicle industry, drive motor system, as one of the three core electrical components of new energy vehicles, is surging.

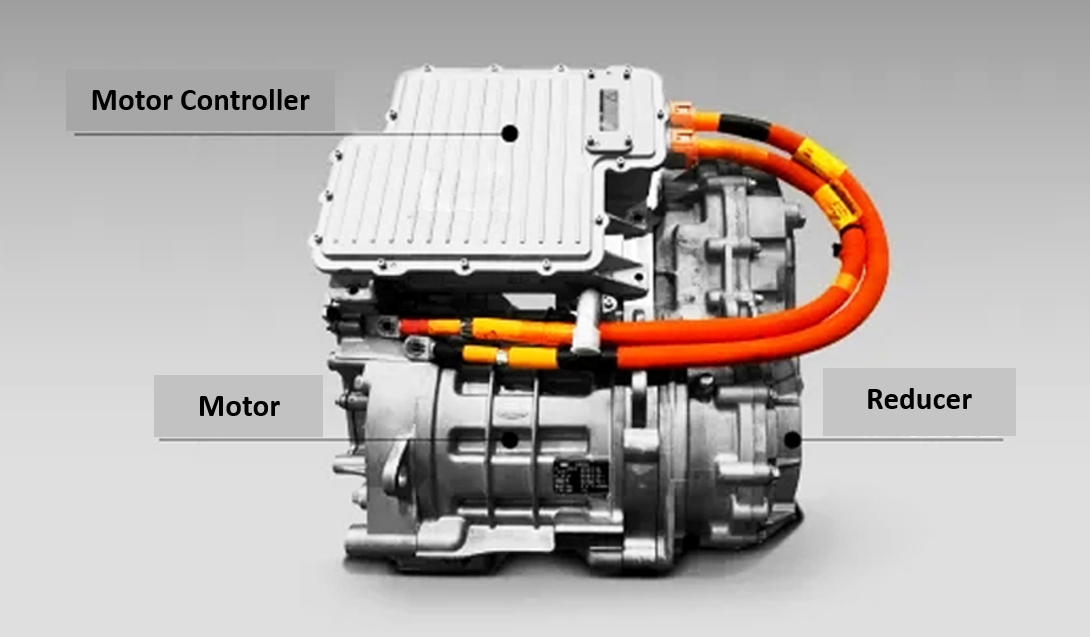

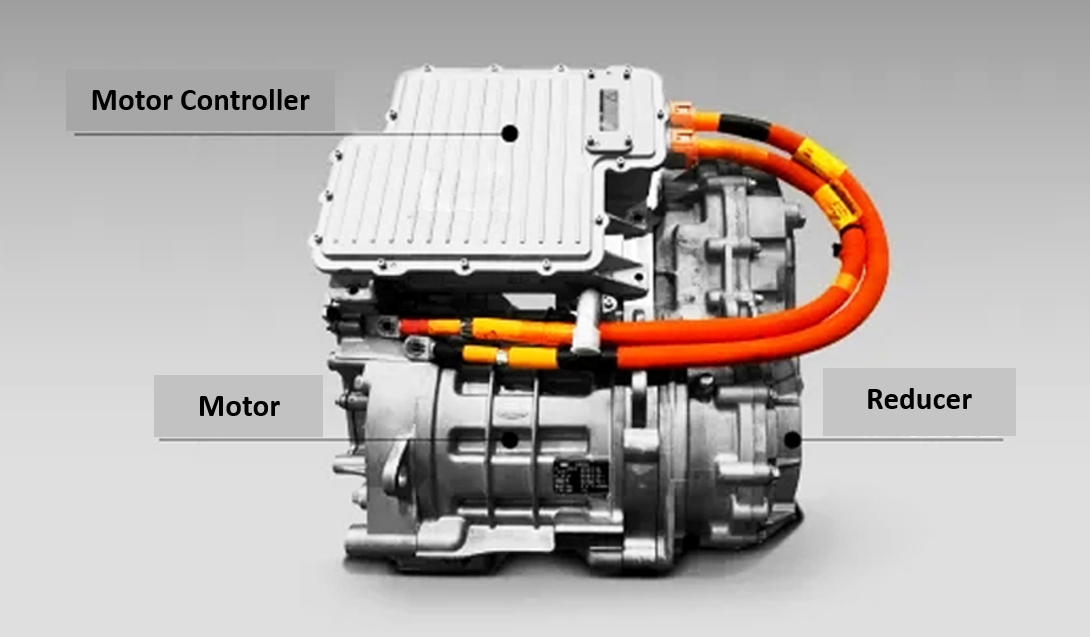

Chart 1 New Energy Vehicle Drive Motor

Technical Requirements of Drive Motor System

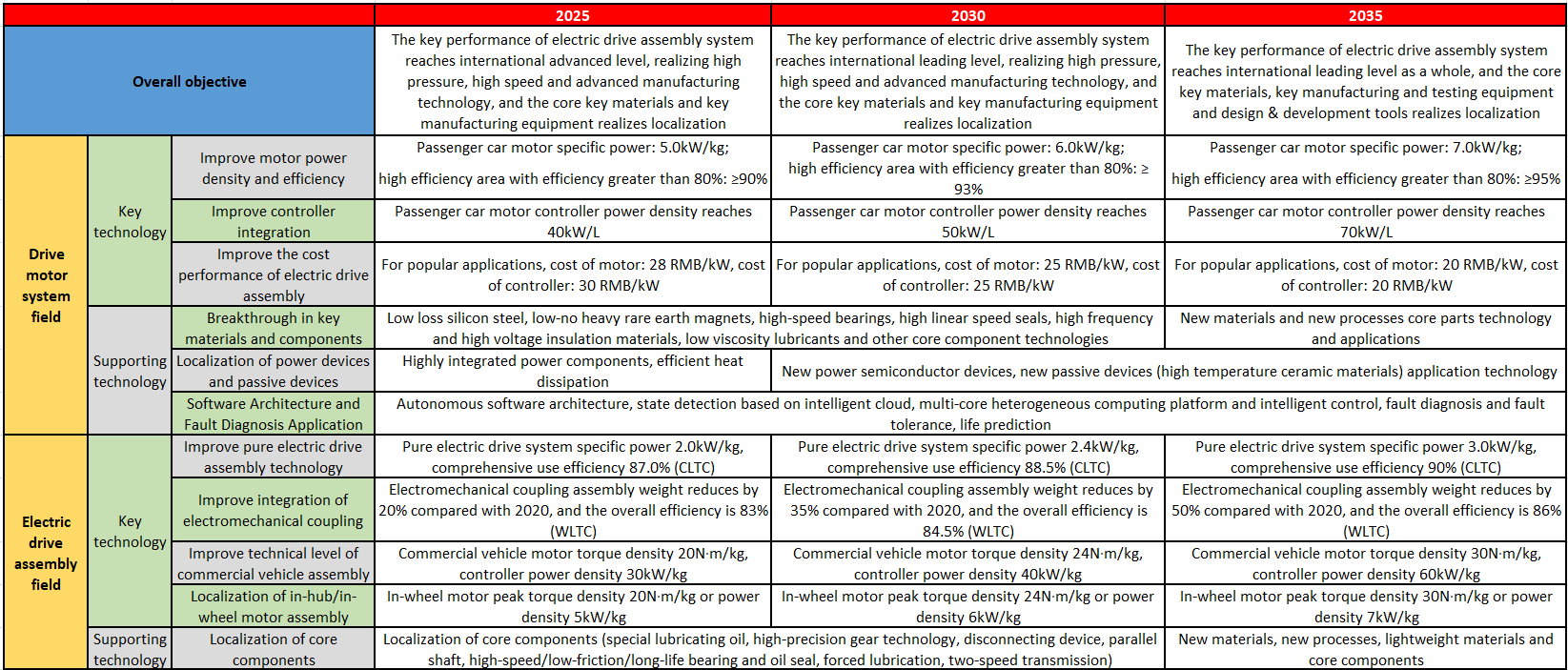

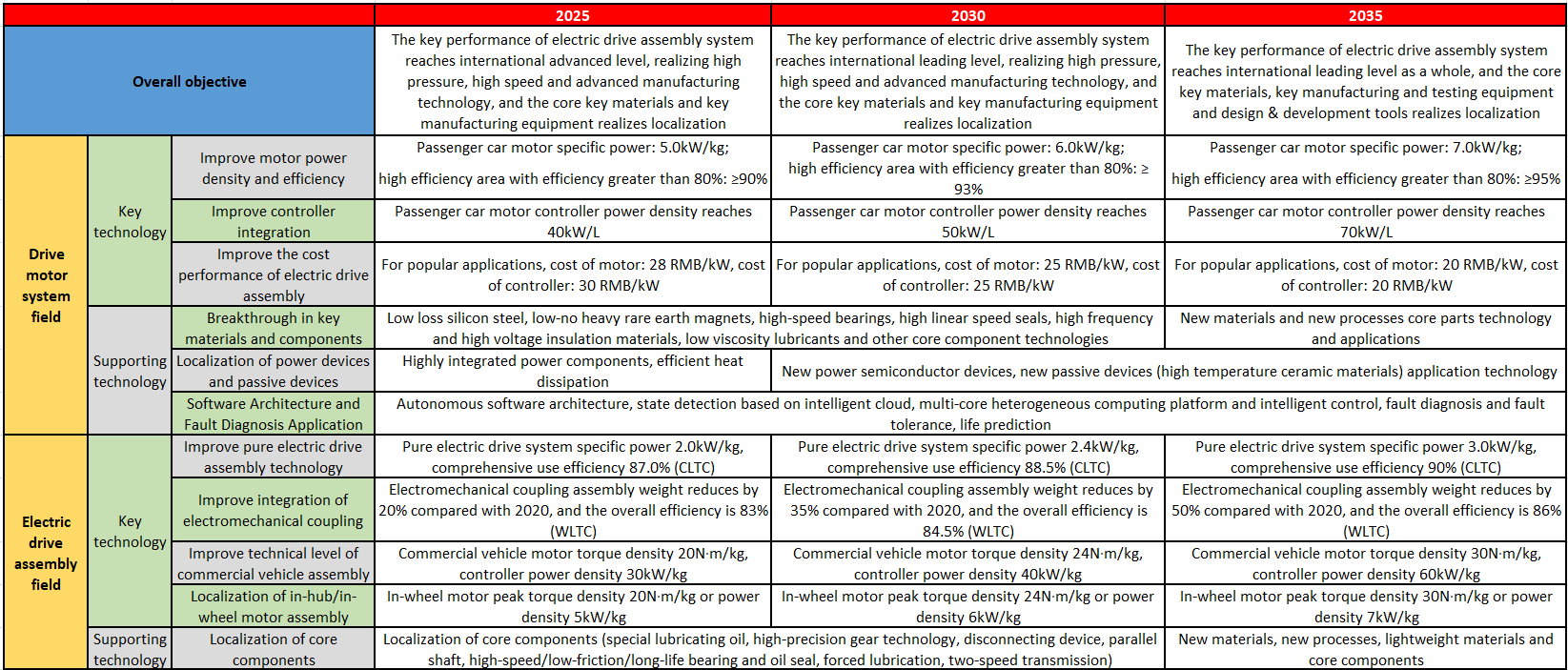

Drive motor is the core of electric vehicle power system, and its performance directly affects the energy efficiency, cruising range and driving reliability of the vehicle. Based on this, China’s authoritative ministries and commissions organized related experts to release the “Energy Saving and New Energy Vehicle Technology Roadmap 2.0”, and made a three-stage development target plan for the technical requirements of new energy vehicle drive motor system.

Chart 2 Drive Motor System Technology Development Planning

Testing Regulations of New Energy Drive Motor

In order to ensure the technical upgrading of drive motor system, strengthen safety regulation and improve product performance and quality, a series of standards and regulations were released by China. Therefore, the drive motor manufacturers need to follow the standards and conduct a comprehensive test for the drive motor in its function and performance.

ISO19453-3-2018《Road vehicles - Environmental conditions and testing for electrical and electronic equipment for drive system of electric propulsion vehicles》

GB/T 29307-2012《The reliability test methods of drive motor system for electric vehicles》

GB/T 18488.1/2-2015《Drive motor system for electric vehicles - General specification/Test methods》

QC/T 1068-2017《Asynchronous drive motor system for electric vehicles》

……

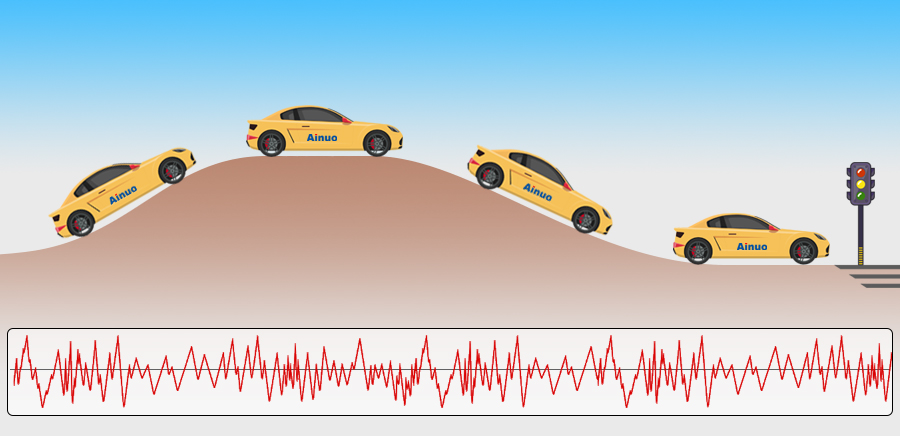

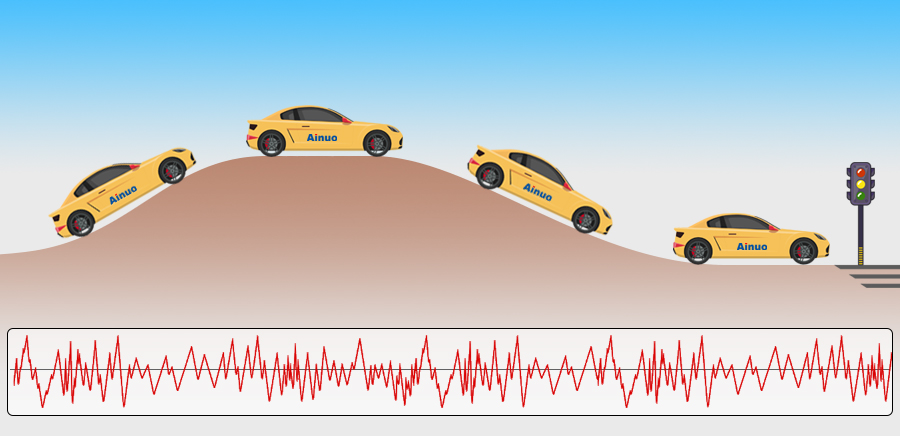

Current Testing Method for Drive Motor

When the manufacturers and OEMs test the drive motor system, testing real batteries cannot meet the test requirements of various complex working conditions. Also, batteries are prone to damage during testing under extreme conditions (such as current spikes caused by emergency braking). Therefore, using battery simulators for driving motor testing and performance evaluation has become the mainstream of electric vehicle drive motor system development and vehicle testing.

Chart 3 Diagram of actual driving conditions simulation

Ainuo ANEVH(F) Bidirectional DC Power Supply Provides Efficient Support

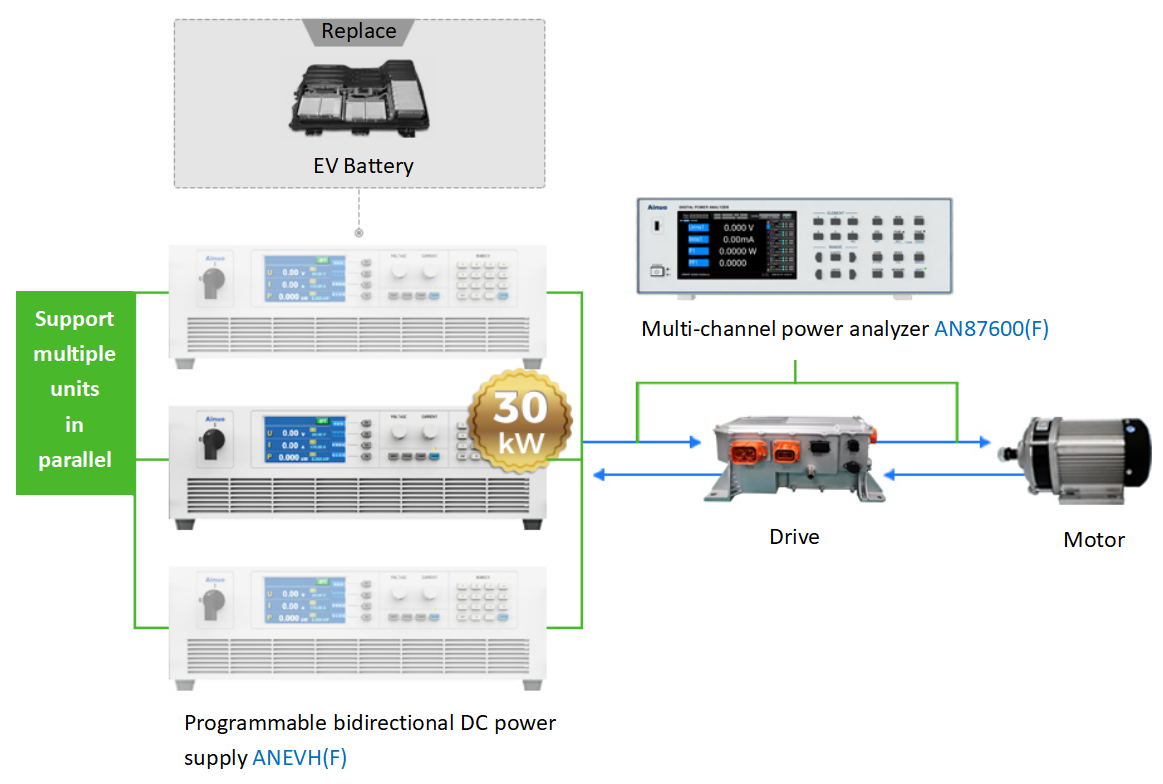

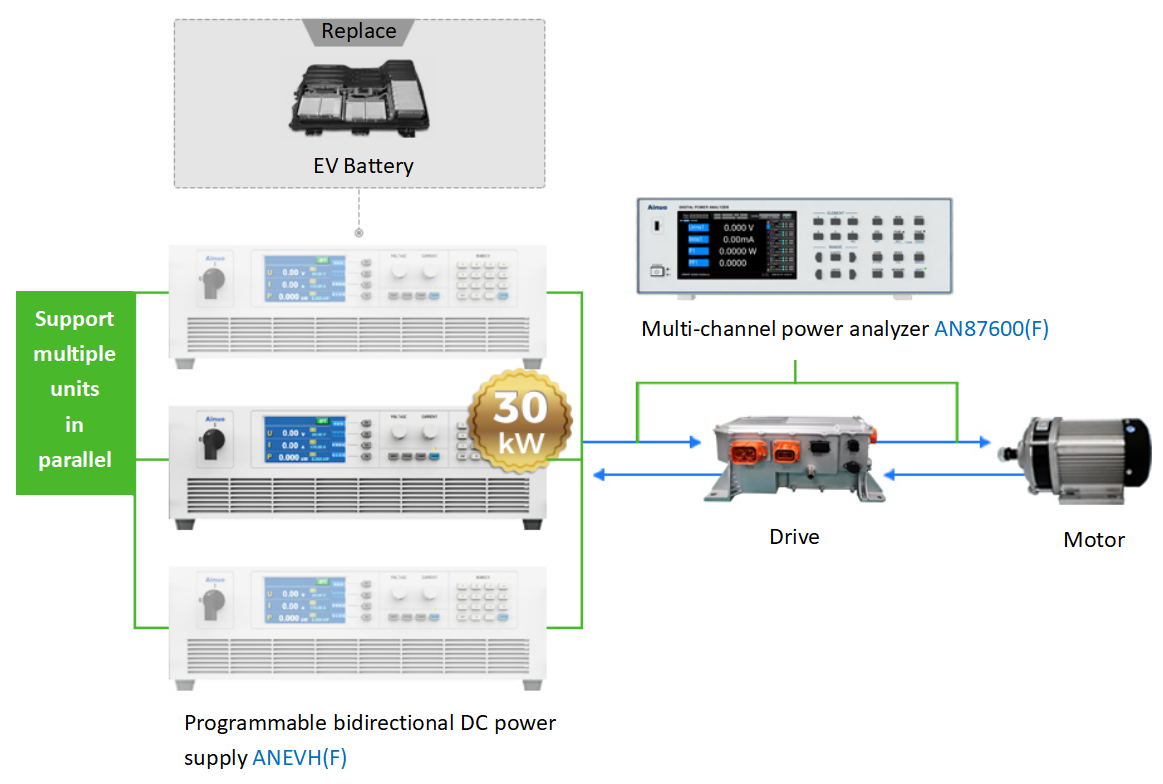

Ainuo Instrument has been deeply engaged in the electrical testing industry for many years, and understands the pain points in the testing of new energy vehicles. The specially developed programmable bidirectional DC power supply ANEVH(F) series can simulate power battery to support drive motor system tests. It can simulate complex driving conditions such as acceleration, braking, etc., and realize the power supply and feedback between the battery and the power system. ANEVH(F) bidirectional DC power supply significantly improves the detection efficiency of the drive motor R&D and production process, saves costs, and greatly supports the production capacity growth.

Chart 4 New energy vehicle drive motor system test diagram

Ainuo ANEVH(F) series programmable bidirectional DC power supply integrates source and load into one device, bidirectional energy flow, extreme fast dynamic response speed, and 1.5ms forward and reverse fast switching. It adopts the energy automatic feedback function and has outstanding advantages of energy saving and consumption reduction. It also adopts active power factor correction technology, and the full load power factor exceeds 0.99.

The machine size is only 3U, single machine voltage range 0-2250V, current range 0-510A, the maximum output power is 30KW; Moreover, it supports multiple units in parallel, and the maximum power can be extended to 1MW, meeting higher power testing needs of customers. The built-in classic battery curves can simplify the modeling work for users. The ANEVH(F) bidirectional DC power supply can produce various types of curves freely, excellent characteristics and prosperous testing functions, suitable for the tests of various types of battery simulation occasions.