If you're developing, validating, or manufacturing micro-inverters, you know the testing challenge all too well. How do you replicate the real world—a dynamic, unpredictable sun—inside the four walls of your lab? For years, the answer has been a cumbersome mix of DC power supplies, load banks, and hoping for a sunny day.

But there's a better way. The secret to faster, smarter, and more cost-effective micro-inverter testing is already here: the Bidirectional DC Power Supply.

Let's break down why this single instrument is a game-changer for your R&D and validation labs.

The Micro-Inverter Testing Dilemma

First, consider what a micro-inverter does:

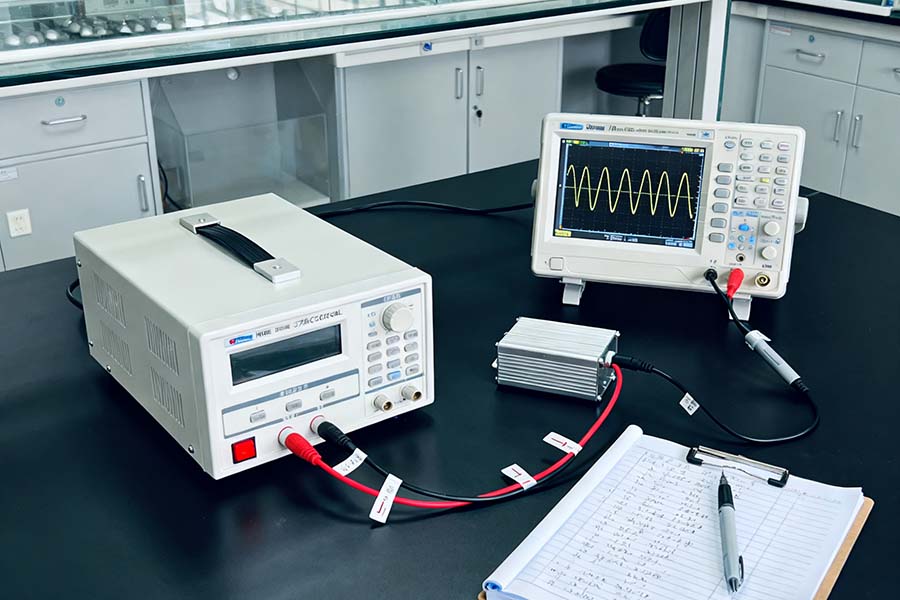

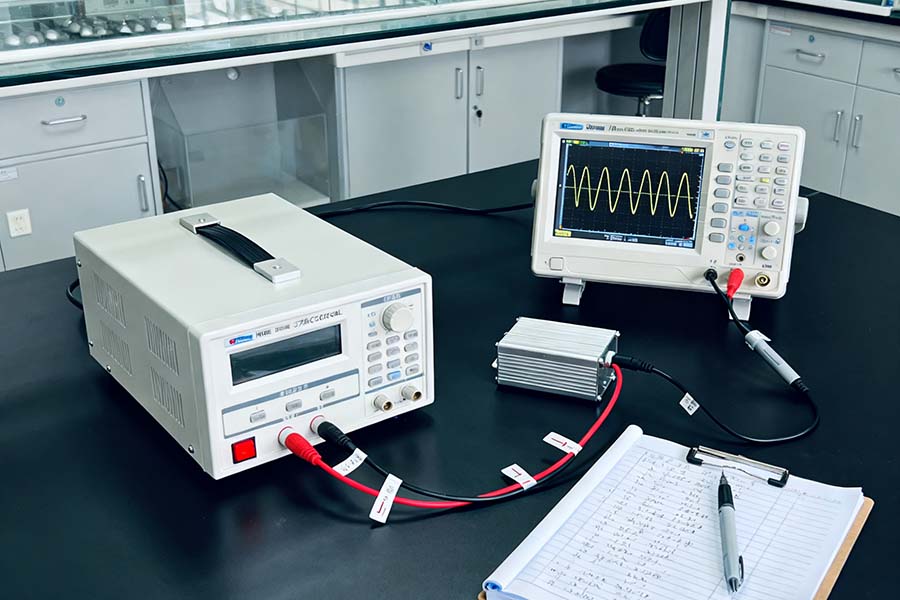

To test it, you need to simulate both sides: a programmable DC source to act as the panel and a programmable DC load to absorb the AC output power. Traditionally, this meant two (or more) large, expensive pieces of equipment—a DC source and a resistive load bank—that together were inefficient and inflexible.

The Bidirectional Solution: One Instrument to Rule Them All

A bidirectional DC power supply simplifies everything by combining both functions into a single, sophisticated unit. It can:

Act as a DC Source: Precisely simulate the voltage and current of a solar panel.

Act as a DC Load: Absorb the power generated by the micro-inverter and regenerate it back to your lab's AC mains.

This dual nature unlocks four powerful advantages that will transform your testing workflow.

Slash Your Operating Costs and Go Green in the Lab

This is the most immediate and impactful benefit. Traditional resistive load banks convert precious electrical energy directly into heat. Testing a 300W micro-inverter for hours means you're literally burning hundreds of watts of power, running up your electricity bill and turning your lab into a sauna.

A bidirectional supply is regenerative. Instead of wasting energy as heat, it captures the AC power from the micro-inverter and sends it back to the building's power system. This can reduce the net energy consumption of your test setup by up to 90%. The savings on your electricity bill quickly add up, making the instrument not just a tool, but a long-term investment.

Unlock Unmatched Testing Capabilities

How do you test how a micro-inverter reacts to a passing cloud? With a traditional setup, it's nearly impossible. With a bidirectional supply, it's a few clicks away.

True PV Emulation: Program the exact I-V curve of any solar panel. You can define open-circuit voltage (Voc), short-circuit current (Isc), and the maximum power point (MPP) to rigorously test the micro-inverter's MPPT algorithm.

Simulate Real-World Scenarios: Create dynamic profiles for:

Rapid irradiance changes (clouds)

Partial shading (complex I-V curves with multiple peaks)

Slow sun ramps (sunrise/sunset)

Full-Power Durability Testing: Safely and efficiently test your micro-inverter at its maximum rated power for days on end, something that is prohibitively expensive and hot with a load bank.

Achieve Unbeatable Precision and Repeatability

R&D and quality assurance demand data you can trust. You can't base your findings on a partly cloudy Tuesday.

Lab-Grade Control: Every test parameter—voltage, current, and power—is digitally programmable. This means you can run the exact same test today, tomorrow, and in six months.

Automate Everything: Develop complex, automated test sequences for efficiency mapping (like CEC or EU efficiency), start-up/shut-down thresholds, and stress tests. This frees up your engineers from manual monitoring and reduces human error.

Faster Time-to-Market: Instantly jump to any test condition. No more waiting for perfect weather. Accelerate your development cycles from days to hours.

Enhance Safety and Protect Your DUT

Testing high-power electronics carries inherent risks. Bidirectional supplies are designed with safety in mind.

Controlled Environment: Perform all testing in the safety of your lab, away from high-voltage solar arrays and the elements.

Programmable Protections: Set hard limits for voltage, current, and power. If the device under test (DUT) behaves unexpectedly, the supply will trip instantly, protecting your valuable micro-inverter from damage.

Safe Threshold Testing: Precisely and safely find the micro-inverter's start-up and shut-down voltages by smoothly ramping the source, a dangerous and difficult task with real panels.

The Bottom Line

While traditional methods like DC sources with load banks or real solar panels have their place, they come with significant compromises in cost, control, and efficiency.

A Bidirectional DC Power Supply is the modern solution. It consolidates your test setup, slashes operating costs, provides unparalleled control, and enables the kind of rigorous, repeatable testing required to build a better, more reliable micro-inverter.