Industry Background and Technical Challenges

With the global penetration rate of new energy vehicles exceeding 35% (according to IEA data in 2025), electric drive system testing faces three core challenges:

1. High dynamic response requirements: Millisecond-level data capture is required for transient motor speed switching from 0 to 15,000 rpm.

2. Complex energy efficiency assessment: System efficiency accuracy must be as low as ±0.1% under an 800V high-voltage platform.

3. Multi-physics coupling: The need to synchronously correlate electrical power data with mechanical parameters such as temperature and vibration.

Core Testing Requirements

Synchronous multi-channel measurement: High-precision synchronous acquisition of motor controller input power (DC), motor output power (AC), and mechanical power (torque/speed) is required to calculate system-level efficiency (such as the product of inverter efficiency η₁ and motor efficiency η₂).

Dynamic operating condition verification: Power flow analysis covering transient processes such as acceleration and energy recovery is required to verify efficiency symmetry in both directions. Complex System Adaptation: Supports real-time, coordinated testing of front and rear axle power in dual-motor four-wheel drive systems, avoiding errors in data splicing from multiple devices.

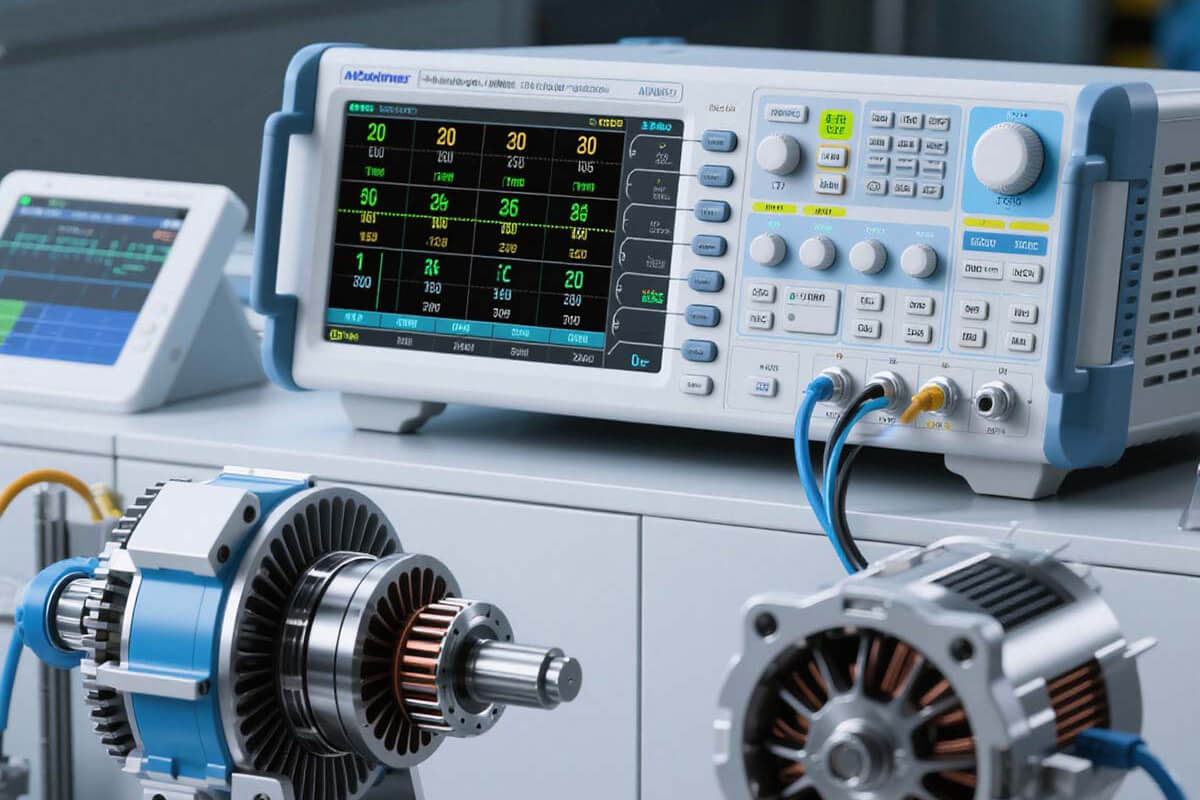

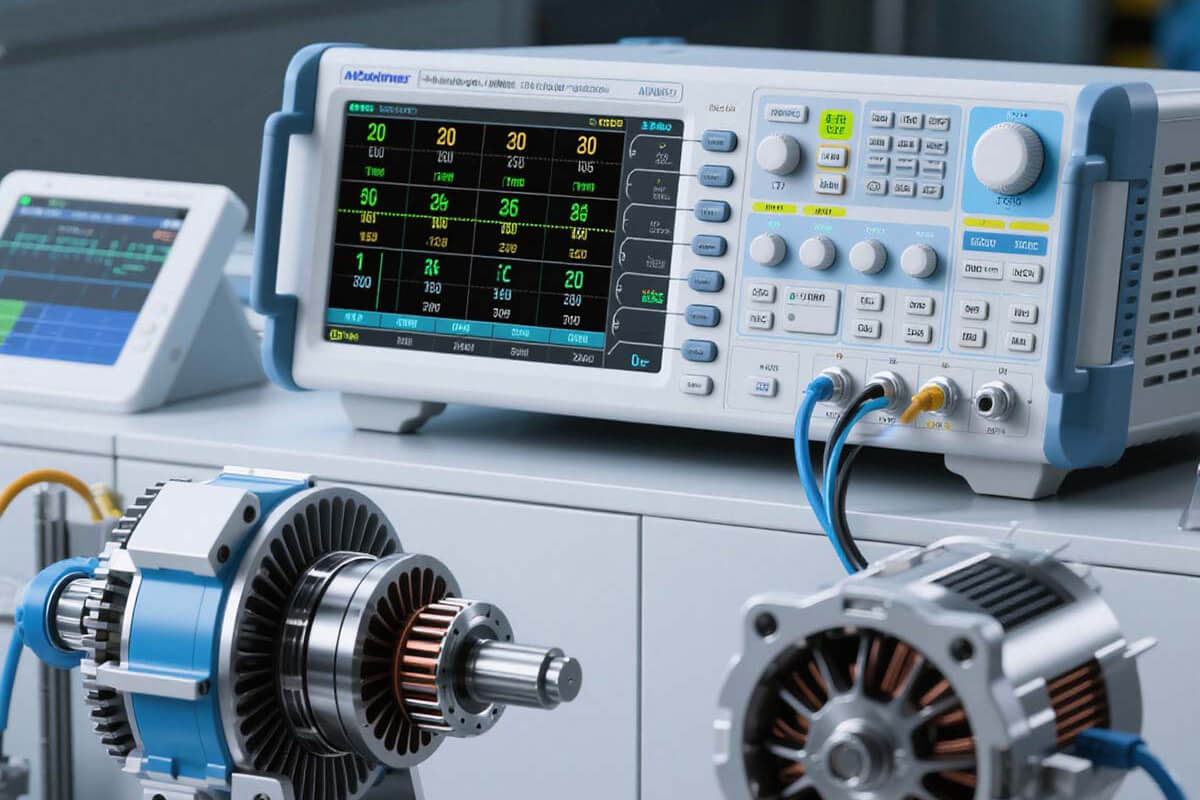

Key Technical Solutions

1. Hardware Requirements

Channel Expansion Capability: At least six power channels (e.g., DC bus + dual three-phase motors), supporting power exceeding 250kW and 500A current sensors;

Accuracy: Basic voltage/current accuracy ≤ 0.05%, frequency bandwidth ≥ 500kHz (e.g., Germany's GMCI LMG671 series);

Synchronous Sampling: All channels use a unified time base, with a sampling rate ≥ 1MS/s, ensuring accurate capture of phase differences.

2. Key Parameter Measurement Matrix

| Test Item | Technical Specification | Typical Instrument | Industry Standard |

| DC Bus Power | Accuracy 0.03% rdg + 0.05% fs | Ainuo ANPA3000 | GB/T 18488-2023 |

Motor Phase Current Harmonics

| Bandwidth: DC, 0.5-1 MHz | IEC 61000-3-12 |

3. Typical Test Scenarios

| Test Object | Measurement Parameters | Solution Features |

| Traction Inverter | Switching Loss, Efficiency Graph, Harmonic Distortion | Three-wire, Three-phase Structure + Bidirectional DC/DC Measurement |

| Dual-Motor Four-Wheel Drive System | Front and Rear Motor Power Allocation Combined Drive Efficiency | 6-Channel Real-Time Linkage |

| Vehicle Energy Management | Charge/Discharge Cycle Efficiency, Endurance Energy Consumption Simulation | Multi-channel Simultaneous Recording of Voltage/Current Transient Response |

4. Software Analysis Features

Efficiency Map Generation: Draws the motor's efficient operating range based on the torque-speed curve;

Loss Quantification Analysis: Identifies power loss components such as iron and copper losses to identify efficiency bottlenecks;

Durability Testing: Continuously records charge and discharge cycle data, supporting semi-automatic long-term operation verification.

Industry Application Value

R&D Optimization: Reduces the verification cycle for innovative power electronics topologies by over 50%;

Production Line Testing: A single device replaces multiple instruments, reducing testing costs by 30%;

Standard Compliance: Meets ISO 7637 electromagnetic compatibility and GB/T 18488 motor test specifications.