Introduction

As the global photovoltaic installed capacity exceeds 1.5TW (2025 data), the performance of the inverter, as the "heart" of the photovoltaic system, directly affects the power station revenue and grid security. The regenerative grid simulator power supply has become the core equipment for inverter testing through high-precision grid environment reconstruction and energy closed-loop technology. This article will conduct a systematic analysis from three dimensions: technical principles, test system, and industry application.

Core Technology

1. Energy feedback technology

Adopting advanced SPWM technology, it has the function of rated power feedback to the grid, and the power supply can operate in four quadrants:

• Feedback efficiency: 100% (rated power section)

• Dynamic response time: <5ms (load mutation scenario)

• Harmonic suppression capability: THDI<3% (meeting IEC 61000-3-12 standard)

2. Smart grid simulation algorithm

FPGA-based real-time digital signal processing (DSP) system supports:

• Grid disturbance waveform library: contains 287 typical fault waveforms (such as voltage surge/sag, frequency offset)

• Adaptive impedance matching: automatically compensates the impedance of the test system and eliminates the influence of reflected waves

• Harmonic injection accuracy: 0.1% level (can simulate 0-50 harmonics)

3. Multi-physics field collaborative simulation

Integrated thermal-electric-magnetic coupling model, verified by ANSYS simulation:

• Heat dissipation design: adopts liquid cooling solution to ensure continuous full power operation at 40℃ ambient temperature

• Electromagnetic compatibility: passed CISPR 16-1-1 Class A certification

Full Life Cycle Test System

1. R&D verification stage

• Extreme working condition test: simulate -40℃~85℃ ambient temperature change, verify inverter MTBF (mean time between failures)

• Grid adaptability test: including:

-Low voltage ride-through (LVRT): maintain operation ≥0.5s at 20% rated voltage

-High voltage ride-through (HVRT): stable operation at 130% rated voltage

-Frequency offset test: 45-55Hz continuously adjustable

2. Production line detection stage

• Automated test platform: use robots to automatically load test sequences, single test cycle ≤120 seconds

• Big data analysis: real-time monitoring of key parameter CPK values through SPC (statistical process control)

3. On-site operation and maintenance stage

• Portable tester: supports 5-minute rapid deployment, with: Power curve scanning function, thermal imaging fault location, wireless data synchronization

Future Technology Trends

1. Digital twin testing: Building a virtual test environment based on real-time data, with a predictive maintenance accuracy rate of 92%+

2. AI-enabled testing: Automatically generate test cases, intelligent diagnosis of fault modes

3. Standard evolution

• The new version of IEC 62109-3 has stricter restrictions on DC components (required <0.5%)

• China CGC certification adds a 10ms-level dynamic response test

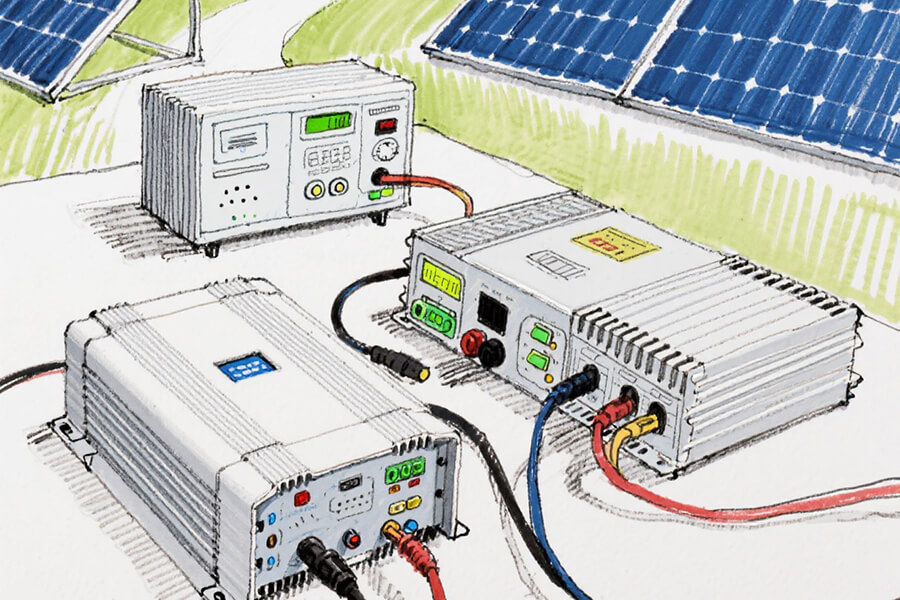

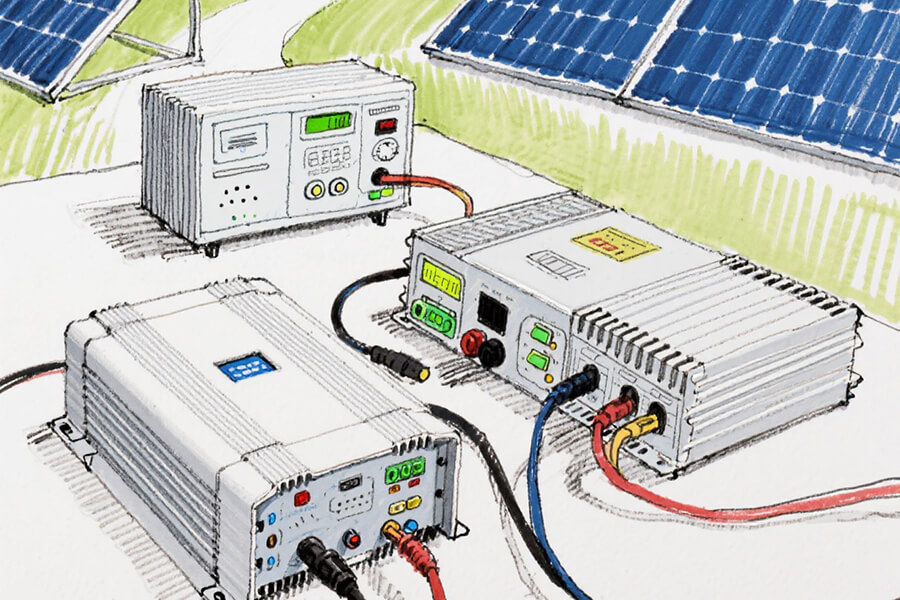

Product Recommendation

Aino regenerative grid simulator power supply ANRGS can simulate abnormal instantaneous rise, instantaneous drop, short circuit, jitter and other phenomena of the mains power, simulate the distortion of the mains waveform, and provide accurate and fast measurement of power parameters. 100% rated power feed back to the grid function, capable of four-quadrant operation, can greatly save energy consumption to reduce operating costs.

Conclusion

The regenerative grid simulator power supply is promoting the transformation of photovoltaic inverter testing from "qualification verification" to "performance optimization" through technological innovation. As the test accuracy moves from 1% to 0.1%, this technology will become a key support for ensuring the 25-year life of the photovoltaic system.