A programmable AC test power supply is a "universal grid simulator" for switching power supplies, used on the production line to accurately, quickly, and automatically verify their reliable operation under various normal and abnormal power grid conditions worldwide.

Why Is the Programmable AC Test Power Supply Necessary for Switching Power Supply Production Lines?

Switching power supplies (such as chargers, adapters, and PC power supplies) may be used in any country and under any power grid environment after leaving the factory. Power grids are not ideally stable and may experience fluctuations, dips, and interference. Production lines must simulate these scenarios to ensure the product:

Safety: No burnout or hazards caused by abnormal input conditions.

Reliability: No downtime and stable performance under harsh power grids.

Compliance: Meet global safety and electromagnetic compatibility standards.

A programmable AC test power supply is designed to efficiently complete these tests.

Specific Test Applications in Production Lines

1. Input Characteristic Test

Test Content: Verify that the switching power supply meets the specified input current, power, power factor (PF), efficiency, and other parameters at the rated voltage (e.g., 220Vac).

The purpose of a programmable power supply is to provide a clean, stable, and accurately measured AC voltage, and to accurately measure electrical parameters at the input to determine if the product's power consumption and energy efficiency meet standards.

2. Regulation Test

Linear Regulation: The stability of the output voltage when the input voltage changes.

Load Regulation: The stability of the output voltage when the output load changes.

The purpose of a programmable power supply is to test linear regulation. Automatically step or sweep the input voltage (for example, from 90Vac to 264Vac) while measuring the output voltage of the switching power supply to determine if the variation is within the specified range (e.g., ±1%).

3. Abnormal Input Test

This is the most core application, used to test the product's robustness.

Voltage Limit Test: Applying the highest (e.g., 275Vac) and lowest (e.g., 85Vac) input voltages to test whether the product can operate normally without damage.

Voltage Ramp-Up/Ramp-Down Test: Simulating slow grid fluctuations to test the power supply's adaptability.

Voltage Sag and Interruption Testing: This test simulates a momentary grid drop (e.g., from 220VAC to 100VAC for 100ms) or a complete power outage (0VAC). The tests include:

Will the product restart or freeze?

Is the output normal after a restart?

Do internal protection circuits (such as undervoltage lockout (UVLO)) operate correctly?

4. Safety & Compliance Pre-test

Many international standards (such as IEC 61000-4-11 and -13) require power supply immunity testing.

A programmable power supply can simulate voltage dips, short interruptions, and voltage variation waveforms defined in the standards on the production line for pre-compliance testing. This significantly increases the chances of a product passing official certification and avoids the costs and delays of subsequent rectification.

5. Dynamic Response Test

Test Content: Simulates a sudden input voltage change (e.g., a step from 180Vac to 240Vac) to test the control loop response speed of the switching power supply, determine whether the output voltage overshoots or oscillates, and how quickly it recovers to a stable state.

The role of the programmable power supply: Provides a high-speed voltage step change signal and monitors the product's response.

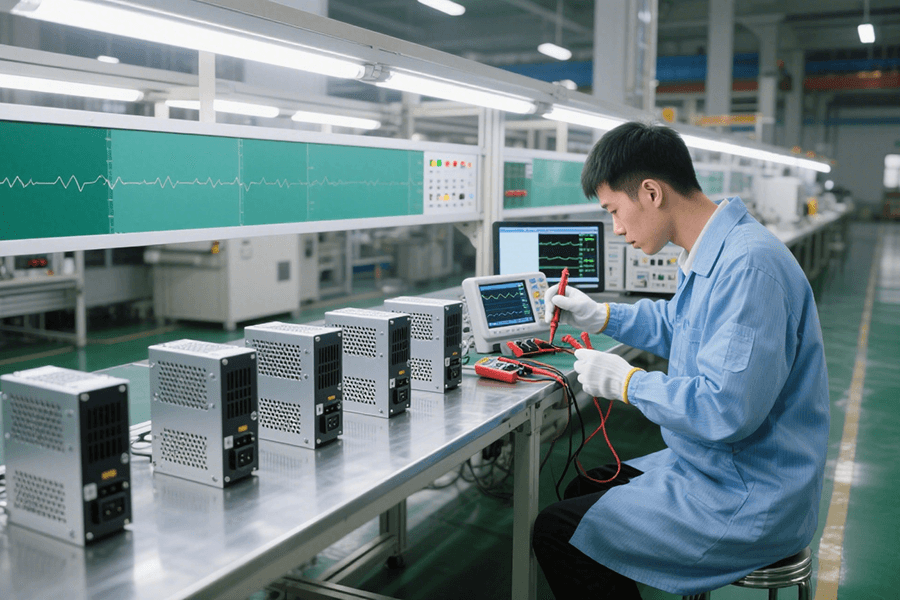

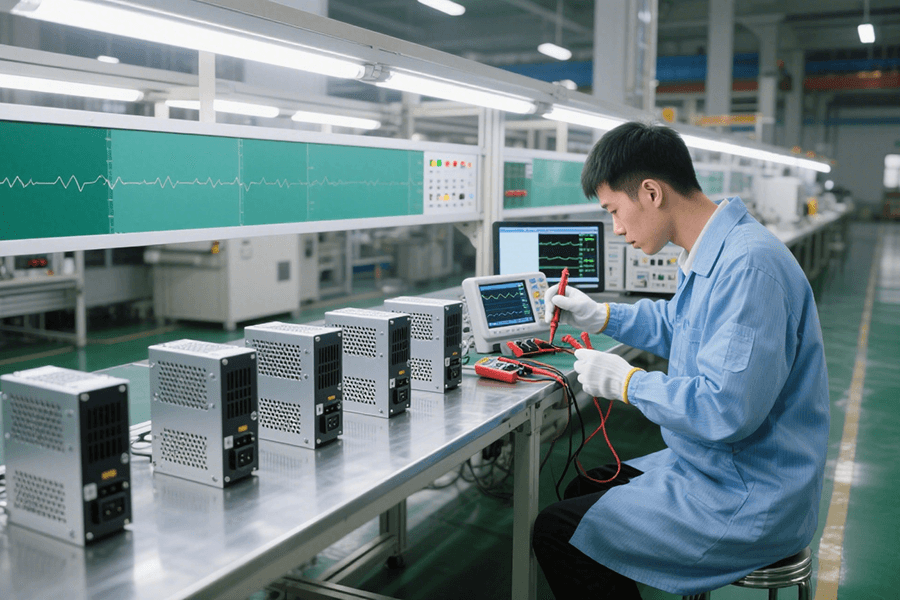

6. Automated End-of-Line Test

Modern production lines are automated. Programmable AC power supplies are a core component of automated test systems (ATE).

Workflow:

A robotic arm connects the switching power supply under test to the test fixture.

Test software controls the programmable AC power supply, sequentially outputting a series of preset voltage conditions (e.g., 90V, 110V, 220V, 264V, plus a voltage interruption) within seconds.

Simultaneously, a programmable DC electronic load is applied, and a data acquisition card measures the switching power supply's output voltage, ripple, and other parameters.

All data is automatically recorded and compared against pre-set acceptable limits, with the software automatically assigning a "PASS" or "FAIL" judgment.

Test results are uploaded to the MES (Manufacturing Execution System) for quality traceability.

Advantages of Programmable AC Test Power Supplies Compared to Traditional Voltage Regulators

Features | Traditional Voltage Regulator (Variac) | Programmable AC Test Power Supplies |

Accuracy | Low, relies on manual reading | High accuracy, digital automatic measurement |

Efficiency | Slow, manual adjustment | Extremely fast, millisecond switching, suitable for automation |

Waveform | Only amplitude modulation, power grid interference directly affects testing | Pure sine wave, stable output, no interference |

Function | Only voltage regulation | Voltage regulation, frequency modulation, simulation of sags, interruptions, and harmonics |

Integration | Not automated | Standard interfaces (LAN, GPIB) for easy integration with ATE systems |

Conclusion

In switching power supply production lines, programmable AC test power supplies have evolved from optional tools to essential core quality control equipment. By simulating the volatility of the global power grid, they ensure the superior quality and high reliability of shipped products, playing a key role in achieving automated production and enhancing brand competitiveness.