Industry background

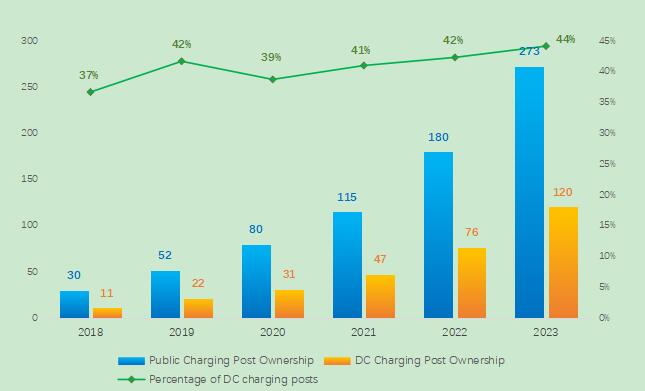

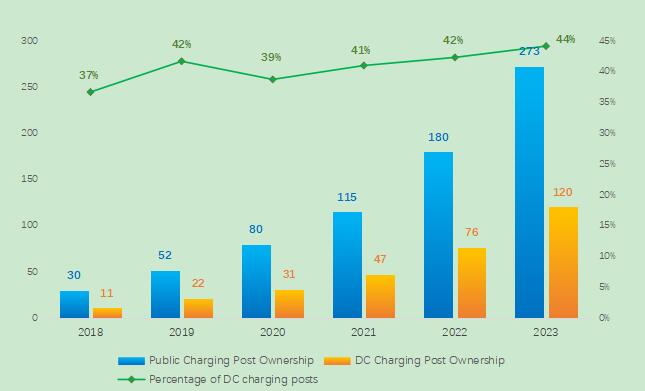

China is the world's largest market for electric vehicles, with nearly 9.5

million new energy vehicles sold in 2023, accounting for more than 60% of the

world's total. As a supporting basic environment, charging facilities are also

developing rapidly.

Industry demand

Compared with the AC charging pile, the power of DC charging pile is

larger, and a single charging module can reach 30kW, and the maximum power of

some super charging piles developed and tested has reached 1MW. With the launch

of 800V platforms for new energy vehicles, higher voltage DC charging piles will

become a trend. In order to ensure that the product meets the relevant

requirements of the DC charging pile, the laboratory needs to be equipped with a

high-power bidirectional DC electronic load to provide accurate and high-quality

battery simulation testing.

China's Public, DC Charging Pile Ownership and DC Share, 2018-2023 (10,000 Units; %)

1. Relevant standard

Domestic charging pile enterprises should not only carry out national

standard testing, but also test according to the more stringent American

standard, European standard and Japanese standard. In response to the

requirements of the market and norms and standards, it is the general trend for

manufacturers to improve the performance test level of new energy vehicle

charging piles.

Electric vehicle charging pile related standards and specifications

(1)Chinese standard

GB/T 18487.1-2023《Conduction charging systems for electric

vehicles - Part 1: General requirements》

GB/T 18487.3-2001《Electric vehicle conduction charging system Electric

Vehicle AC/DC charger (station)》

GB/T 20234.1-2023《Connectors for conductive charging of electric vehicles -

Part 1: General requirements》

GB/T 20234.2-2023《Connectors for conductive charging of electric vehicles -

Part 2: AC charging interfaces》

GB/T 20234.3-2023《Connections for conductive charging of electric vehicles

- Part 3: DC charging interfaces》

GB/T 29316-2012《Technical requirements for power quality of electric

vehicle charging and changing facilities》

GB/T 28569-2012 《Electric energy measurement of electric vehicle AC

charging pile》

GB/T 27930-2023《Communication protocol between electric vehicle

non-on-board conduction charger and battery management system》

GB/T 34657.1-2017《Conducted-charging interoperability test specification

for electric vehicles - Part 1: Power supply part》

GB/T 34658-2017《Test consistency of communication protocol between electric

vehicle non-on-board conduction charger and battery management system》

(2)CQC

standardCQC 3170-2018 《Technical specification for energy saving

certification of electric vehicle non-on-board charger》

CQC 3169-2018 《Technical specification for energy-saving certification of

electric vehicle AC charging pile》

(3)IEC

standardIEC 61851-1-2017《Charging systems for electric vehicles - Part 1:

General requirements》

IEC 61851-21-1-2017《Conductive charging systems for electric vehicles -

Part 21-1: EMC requirements for conductive on-board chargers for electric

vehicles connected to an AC/DC power supply》

IEC 61851-23-2014《Conduction charging system for electric vehicles. Part

23: DC electric vehicle charging stations》

IEC 61851-24-2014《Electrically conductive charging systems for electric

vehicles - Part 24: digital communication for DC charging》

(4)EN

standardEN 61851-1-2011《Electric vehicle conductive charging system. Part

1: General requirements》

EN 62196-1-2014《Plugs, sockets, vehicle connectors and vehicle jacks.

Conduction charging of electric vehicles, general requirements》

CLC/TS 50457

2.Problem spot

(1) The integration of the test system is low

(2) Unable to meet multinational testing standards

(3) Fast technology upgrade, poor flexibility of test equipment

(4) High power test cost pressure

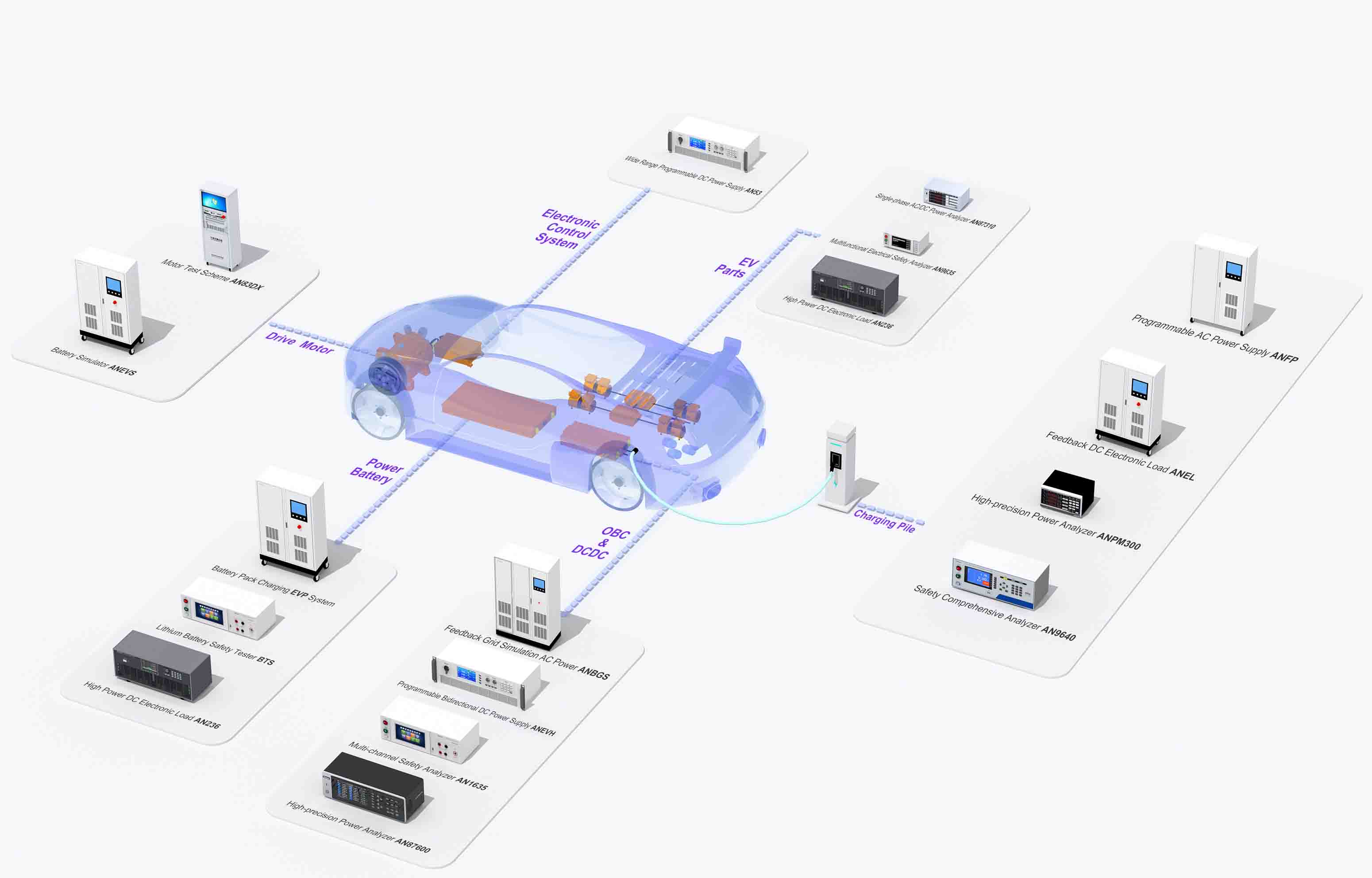

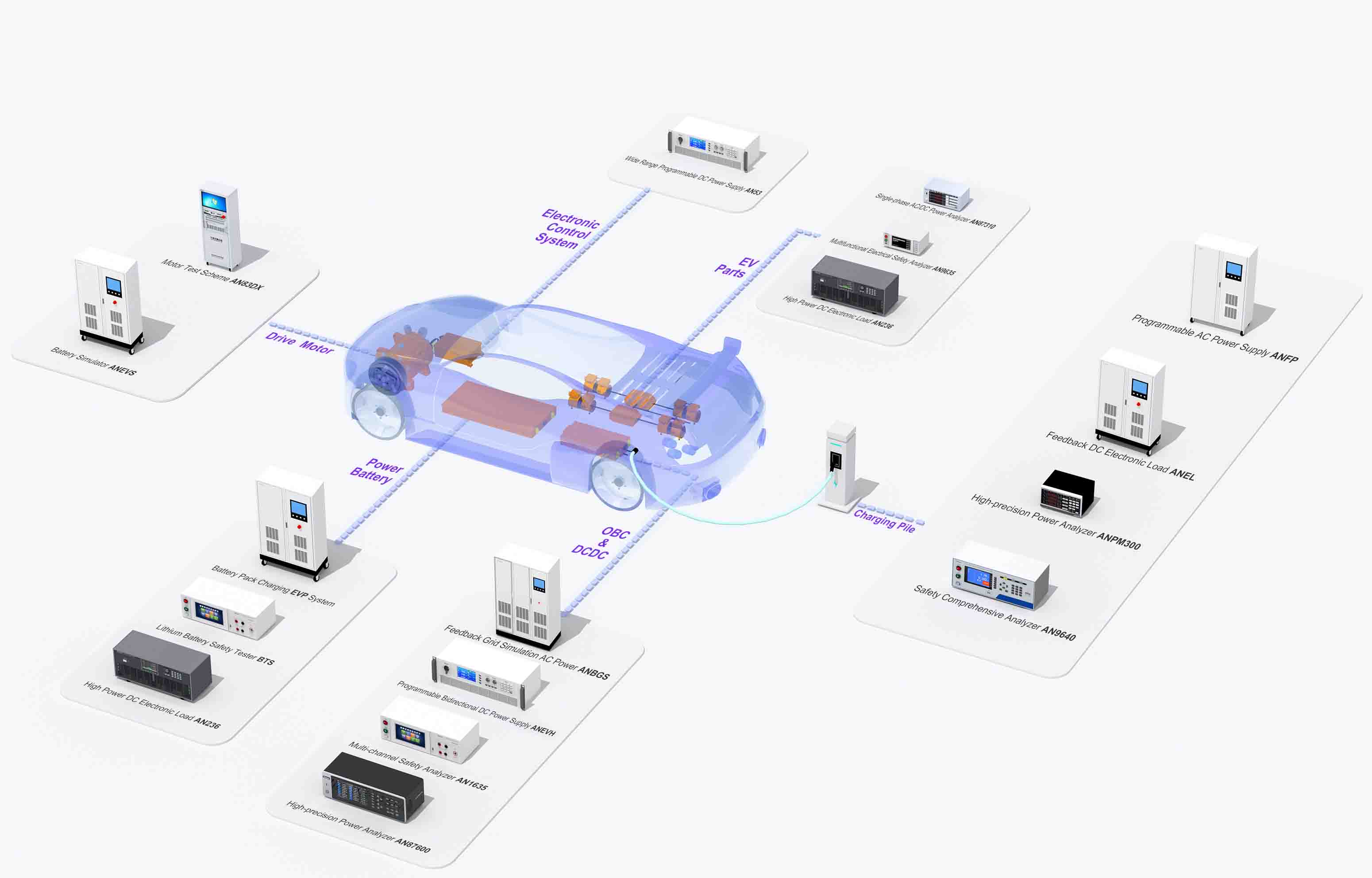

Solution

Ainuo has been deeply engaged in the new energy vehicle industry for many

years. Aiming at the testing difficulties of DC charging piles, AINUO has

launched the high-power bidirectional DC electronic load ANEL(F) series, which

can simulate the power battery of new energy vehicles to a large extent. Single

machine maximum voltage 1200V, with battery simulation function, can simulate

lithium manganate, lithium cobalt acid, lithium iron phosphate, lead-acid,

nickel-metal hydride five battery functions. Can customize cell capacity, number

of series parallel, SOC and temperature parameters.

1.Pain points solved

Highly integrated: with the function of source-load integration, the upper

computer software highly simulates the power battery;

High precision and high dynamic performance output: solve the problem of

not being able to meet the increasingly stringent testing requirements and the

compatibility of different national testing standards;

High flexibility: support the same type of parallel and serial machines,

parallel and serial machines are simple and convenient;

With power feedback function: the efficiency of feedback can reach more

than 90%, saving electricity costs.

2.Product characteristics

(1)Highly integrated: with the function of source and load, the upper

computer software highly simulates the power battery

(2)High precision, high dynamic performance output: to solve the problem

that can not meet the increasingly stringent test requirements, compatibility of

different national test standards

(3)High flexibility: support the same type of parallel machine, string

machine, parallel machine, string machine simple and convenient

(4)With power feedback function: feedback efficiency can reach more than

90%, saving electricity

(1) source-loaded all-in-one machine with pure load mode;

(2) CV, CC, CP, CR working mode;

(3) Voltage 0.05%FS, current 0.1%FS, power 0.2%FS;

(4) Minimum current 0A, minimum power 0kW;

(5) Response time ≤3ms; Switching time <4ms;

(6) Power factor ≥0.99, current harmonics <3%;

(7) 900-step programming ability, 1mS minimum programming time;

(8) Simulation of 7 battery types: ternary lithium, lithium iron phosphate,

lithium titanate, lithium cobalt, lithium manganate, nickel-metal hydride and

lead acid;

(9) Supports 1st, 2nd, and 3rd grade battery models andinternal resistance

models, and allows for import andexport of data in CSV and mat formats.;

(10) Multiple parallel mode, support multiple parallel output of the same

type of load,

(11) CAN, RS232/RS485, LAN and other communication interfaces.

Peroration

Ainuo high-power bidirectional DC electronic load ANEL(F) series, using

high-frequency PWM rectification and bidirectional DCDC conversion technology,

FPGA digital control technology, advanced digital control technology, ultra-high

control precision, fast response speed, wider output voltage range, compared

with conventional bidirectional power supply, can achieve full range of high

precision output of 24V~ full scale. Maximum voltage up to 2000V, single maximum

power up to 1MW. With its excellent performance, the ANEL series has won the

common favor of many manufacturers, and is a feedback load solution and load

alternative for equipment replacement for the testing needs of the DC charging

pile industry.