Anodizing

Ainuo DC Power is a manufacturer of custom power equipment installed for anodizing. Ainuo’s expertise in power control and conversion has helped them become a global leader for the supply of anodizing rectifiers.

Anodizing Rectifiers

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. The process is called anodizing because the treated part forms the anode electrode of the applied electrical circuit. Anodizing increases wear and corrosion resistance as well as improves surface adhesion for paint primers and glue.

The anodized layer is grown by passing direct current (DC) from the anodizing rectifier through an electrolytic solution. The part being anodized is the positive electrode, the anode. The current flow releases hydrogen at the negative electrode, the cathode, and oxygen at the surface of the part increasing the oxide layer.

DEFINING ANODIZING

Anodzing is an electrochemical process by which an oxide layer is grown on the surface of a substrate, in this case aluminum.This is accomplished by placing the work piece in an electrolytic solution and passing current through it to a second piece called an electrode.In this case, the work piece forms the anode of the cell, a lead plate forms the cathode and the electrolytic solution is a mixture of sulfuric acid and water.

WHY TO ANODIZE ALUMINUM

The advantages of anodizing are two-fold,The first advantage is the stunning color that may be imparted to the piece.The second (and debatably more useful) advantage is the dramatic increase in hardness of the surface.The surface effectively becomes sapphire (Al2O3) when anodized.6061 is a common alloy of aluminum because it is the least expensive to purchase and fairly easy to machine.Alloy 6061 also happens to be the easiest to anodize.The hardness of this alloy is less than 25 on the Rockwell C scale.Anodized aluminum has hardness close to 80.For comparison, diamond tops the scale with a hardness of approximately 100.

WHAT IS REQUIRED TO ANODIZE A POWER SUPPLY

Anodizing requires some special equipment.The first piece of equipment is the power supply,Anodizing can be done with many different kinds of power supplies,however, if you want to predict the timing for your anodizer, your options are fewer.In such a case it is necessary to have either a constant-voltage or a constant-current supply.Many people use automotive battery chargers to anodize; these are examples of constant-voltage supplies. A constant-current supply allows the voltage across the cell to vary while maintaining the current through the cell at some value.Below is a schematic of my power supply, which is of the constant-current variety.

Cleaning

Ainuo DC Power is a manufacturer of custom power equipment installed for cleaning. Ainuo’s expertise in power control and conversion has helped them become a global leader for the supply of cleaning rectifiers.

Cleaning Rectifiers

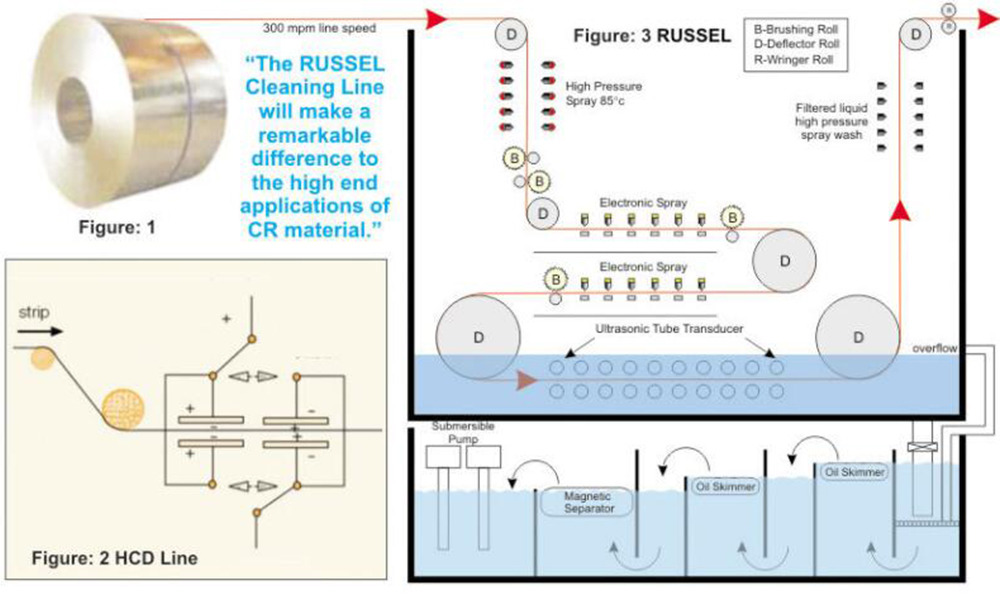

Cleaning is an electrolytic process for surface treatment used to remove impurities such as stains, rust or scale from ferrous metals. The cleaning process is achieved with the aid of an applied voltage potential in the presence of a medium which conducts electricity, wherein the metal is one electrode submerged in the electrolyte. The cleaning rectifier, normally “reversing” (being able to switch the polarity of the output that changes the anode / cathode relationship), provides the voltage potential to the application to affect the cleaning.