Application Enterprise

As a leading enterprise in China’s electric bicycle industry, XX Group has become the world’s leading manufacturer of personal electric transportation. It has many intelligent manufacturing factories in various provinces and regions in China, with an annual production of over 6 million vehicles and the top five in international sales. The products cover three categories: electric bicycles, electric mopeds and electric motorcycles. The group has continued to lead the development of core technologies for electric vehicles for many years. As an industry standard promoter and industry progress leader, it has self-developed core technologies such as motor, display, control, battery system, etc.

Application Background

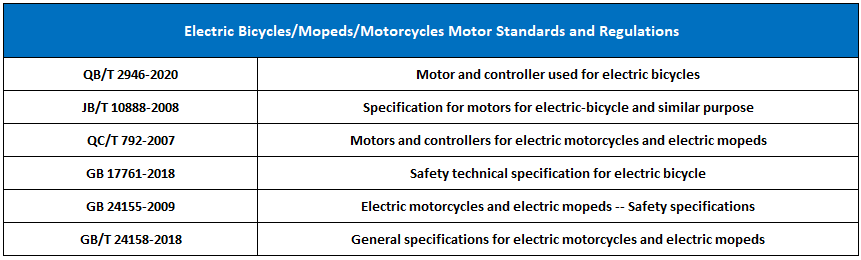

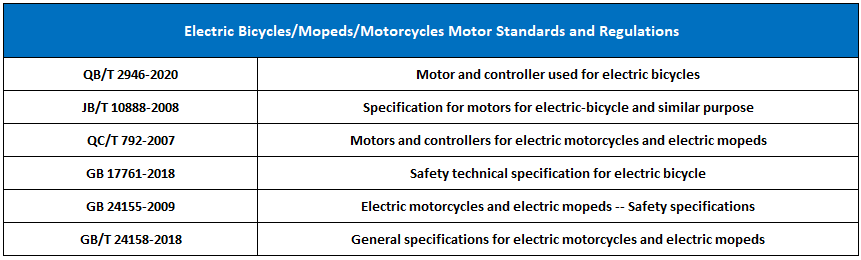

The motor, as the core component of electric bicycles, has higher safety and functional indicators than general electric motors, and the testing standards are also more stringent. Therefore, in the production of electric bicycle motors, every process from the stator to the assembly needs to undergo strict testing to ensure that its rated parameters, efficiency and electrical performance indicators meet the usage requirements in various working conditions.

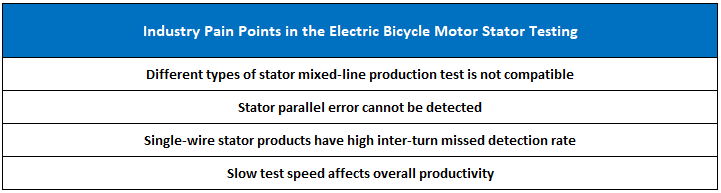

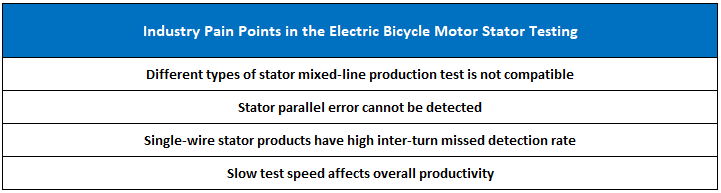

Industry Pain Points

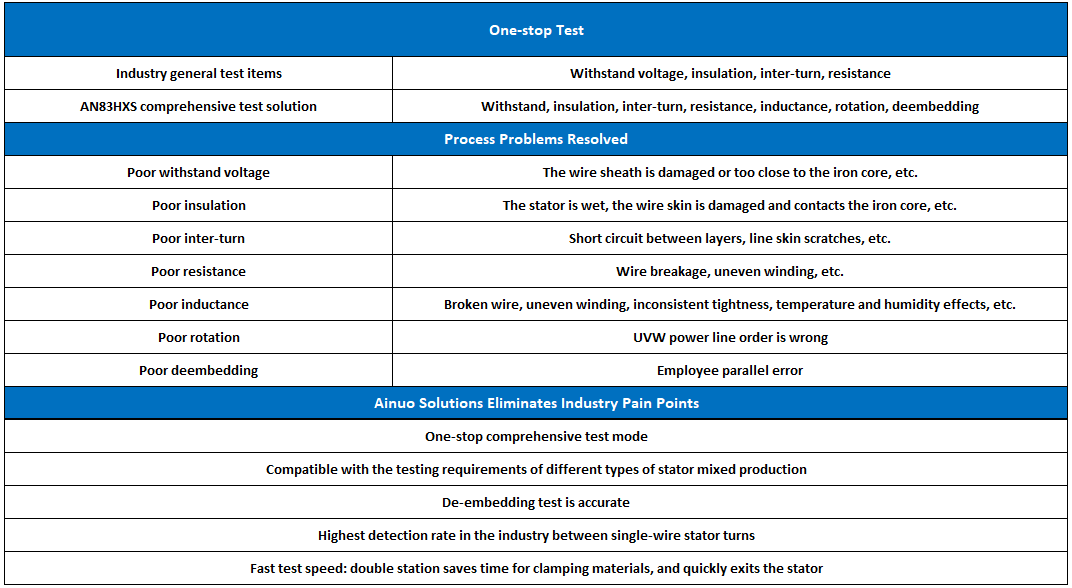

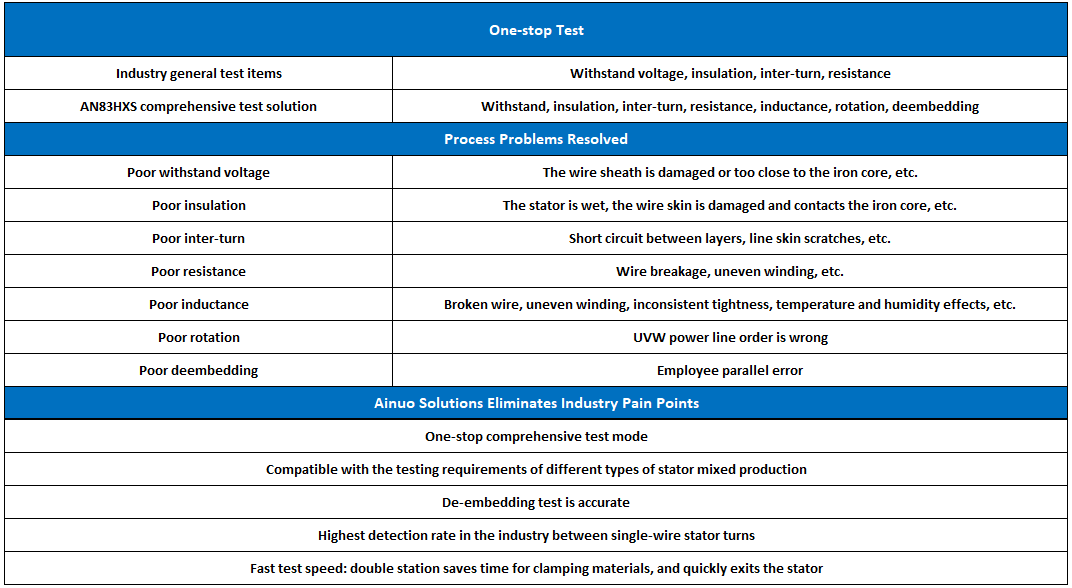

In the actual production and operation of electric bicycle motors, the traditional manual testing cannot guarantee the consistency and actual pass rate of each process, and there are a lot of pain points in the testing. Therefore, a comprehensive automatic testing is particularly important in the closed-loop production of electric bicycle motor stators.

Solutions

Ainuo Instrument has been deeply cultivated in the industry. Aiming at the pain points in electric bicycle testing, Ainuo developed AN83HXS electric vehicle stator comprehensive test solution which is suitable for electric bicycles, electric tricycles, electric mopeds, high-speed motorcycles, electric scooters, etc. motor stator test. The one-stop test mode greatly improves the testing efficiency of the manufacturer's motor R&D and production process, saves equipment costs, and supports production capacity growth.

Implementation Results

AN83HXS Electric Bicycle Stator Comprehensive Test

Final Word

Ainuo AN83HXS electric bicycle stator comprehensive test solution solved the pain points for the XXX group, improved the testing efficiency of the production process for the manufacturer, and provided strong support for its production capacity growth. As a well-known enterprise in the testing industry, Ainuo Instrument launched the AN83HXS series test scheme which has been applied in batches online in many electric bicycle and motor manufacturers, and has been unanimously recognized by major enterprises. Ainuo Instrument has always adhered to the original intention of craftsmanship, and will provide customers with accurate, efficient and first-class power electronic testing solutions as its mission.